Common Issues and Solutions in Gear Design

Introduction

Gears are essential components in many mechanical systems, and their design is crucial for the efficient and reliable operation of machinery. However, the design process is fraught with challenges that can impact the performance and lifespan of the gears. In this blog, we explore some of the common issues in gear design and provide solutions to address these problems.

Common Gear Design Issues and Solutions

1. Inadequate Load Capacity

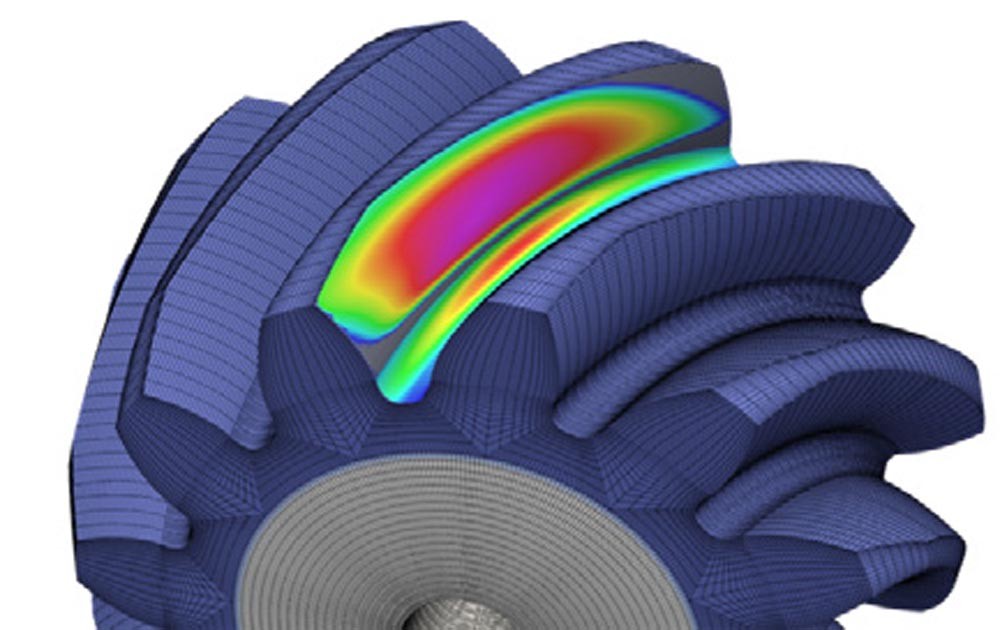

•Problem: Gears that cannot handle the required load may fail prematurely.

•Solution: Utilize advanced materials and heat treatments to enhance the load-bearing capacity. Employ finite element analysis (FEA) to predict and optimize gear performance under various load conditions.

2. Misalignment

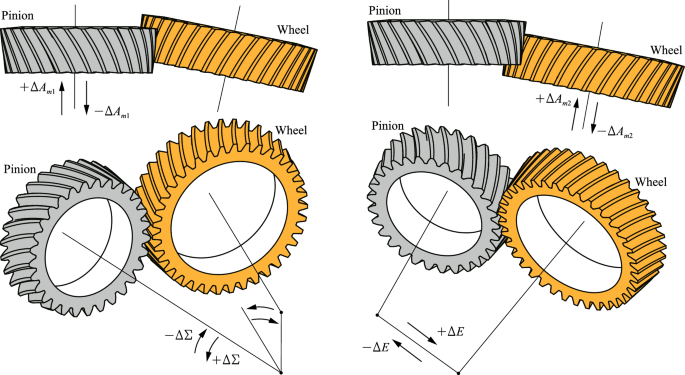

•Problem: Misalignment can cause uneven wear and increase the risk of gear failure.

•Solution: Ensure precise alignment during assembly. Use high-precision manufacturing techniques and incorporate alignment features in the gear housing design.

3. Gear Noise

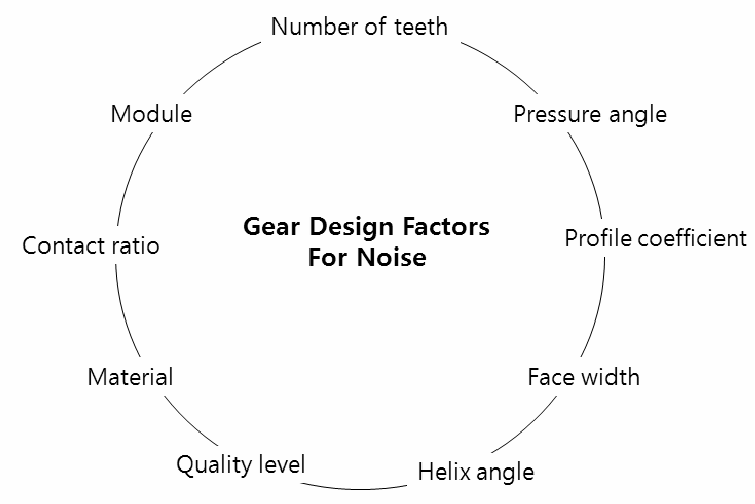

•Problem: Excessive noise can indicate poor gear meshing and impact the overall performance.

•Solution: Optimize gear tooth profiles to ensure smooth meshing. Use noise-damping materials and consider employing helical or herringbone gears to reduce noise levels.

4. Wear and Tear

•Problem: Wear reduces the gear's lifespan and efficiency.

•Solution: Select appropriate materials with high wear resistance. Apply surface treatments like carburizing or nitriding to improve surface hardness. Regular lubrication maintenance is essential to minimize wear.

5. Temperature Effects

•Problem: High operational temperatures can degrade gear material properties and cause failure.

•Solution: Design for adequate cooling and ventilation. Use materials with high thermal stability and consider incorporating thermal barriers or coatings.

Conclusion

By addressing these common issues in gear design, engineers can enhance the performance, reliability, and longevity of gears. At PairGears, we are committed to providing high-quality gear solutions tailored to meet your specific needs. Visit our website for more information and expert advice on gear design.

If you want to learn more about gear design, you can visit the following websites and watch videos to learn.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer ben@pairgears.com.