Forging

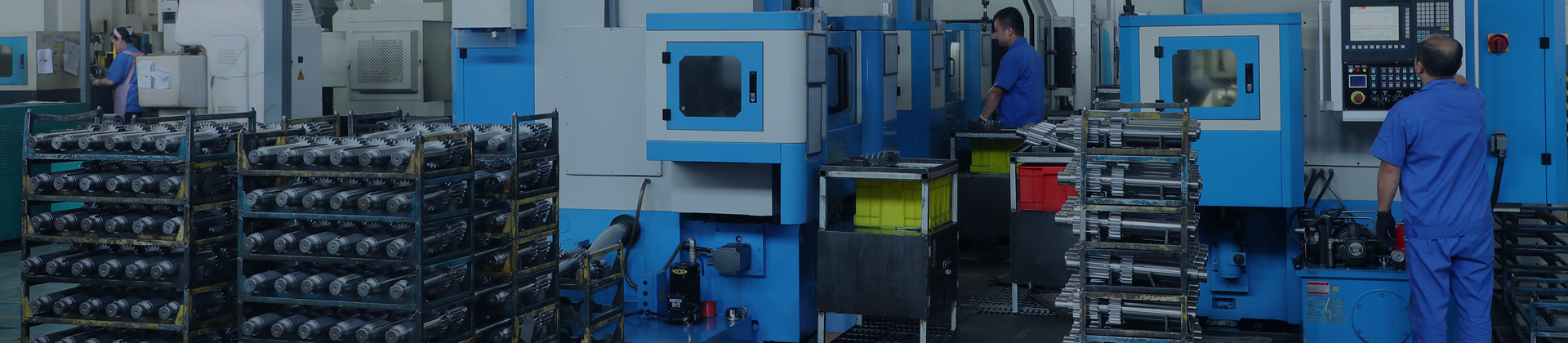

Our manufacturing capabilities

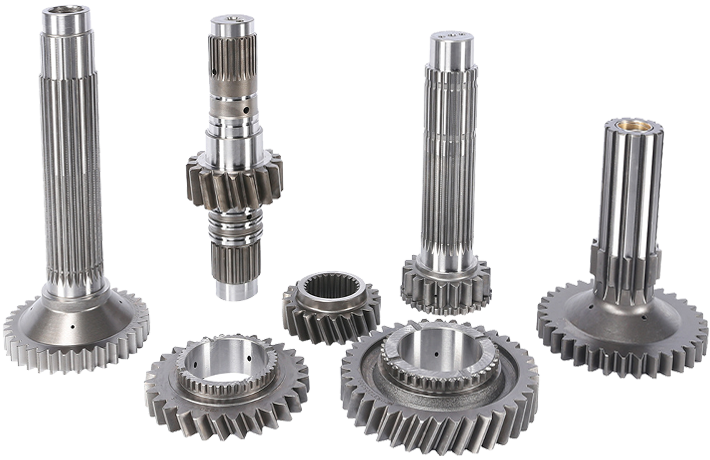

Precision Gear and Shaft Manufacturing Exceeding Standards

Home / Precision Craftsmanship that Exceeds Standards

PairGears doesn't just manufacture products, we provide our customers with durable, precision engineered solutions. Our manufacturing process covers every detail from raw material selection to final product shipment, ensuring every step meets or exceeds industry standards. Here's how we do it.

Gear Manufacturing

Gear Production Process

Every step is the art of polishing gears

Lathe processing

Hobbing

Gear shaping

Shaving teeth

Broaching machine

Heat treatment

Grinding teeth

CNC machine tools

Shot blasting

Clean & rust prevention

Package

Forging Blanks

Selection and customization

Our forging process starts with the selection of high-quality raw materials and uses advanced forging technology to ensure that the blank has a uniform structure and excellent mechanical properties. Compared with traditional mass production, our customized approach allows for more meticulous quality control and flexible design adjustments, ensuring that each blank lays a solid foundation for subsequent processing.

Roughing lathe

Pay equal attention to precision and efficiency

In the rough machining stage, our lathes adopt the latest automation technology, which not only ensures machining accuracy, but also significantly improves production efficiency. We are able to process large quantities of blanks quickly and accurately while ensuring each product meets strict dimensional requirements.

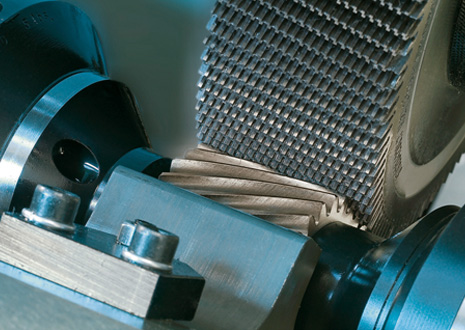

Hobbing

Automated and efficient production

Gear hobbing machine processes by using hobbing cutter to roll and press, which can quickly and efficiently produce a large number of gears, improving production efficiency; at the same time, it can ensure the accuracy and quality of gears, avoiding errors and deformation that may occur in traditional cutting processes; furthermore, gear hobbing machine requires only a small amount of cutting during the processing, not only reducing material waste, but also saving energy and costs.

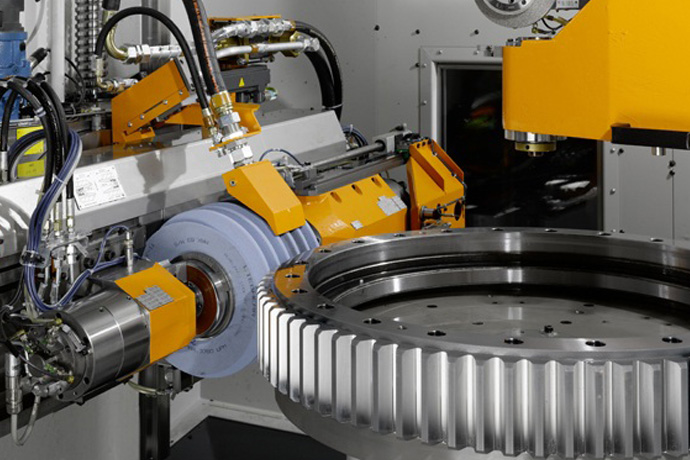

Grinding teeth

Grinding ensures accuracy and perfect matching

Gear grinding can achieve smooth and flat gear surfaces, reduce noise, improve gear wear resistance and transmission efficiency; we have multiple German KAPP gear grinding machines, which can achieve the highest precision DIN4 level (ffa cumulative error can reach within 2μm) gear processing, ensuring precise gear transmission.

Leading technology, diverse choices

Our finishing processes include gear hobbing, gear shaping, gear shaving, gear grinding, broaching and CNC machine tool processing. These processes use industry-leading technology and equipment to ensure that every gear and component can achieve the highest precision and performance. standard. Unlike other companies that rely on a single technology, our diverse technology selection allows us to provide our customers with the best solutions.

Gear shaping

Shaving teeth

Broaching machine

CNC machine tools

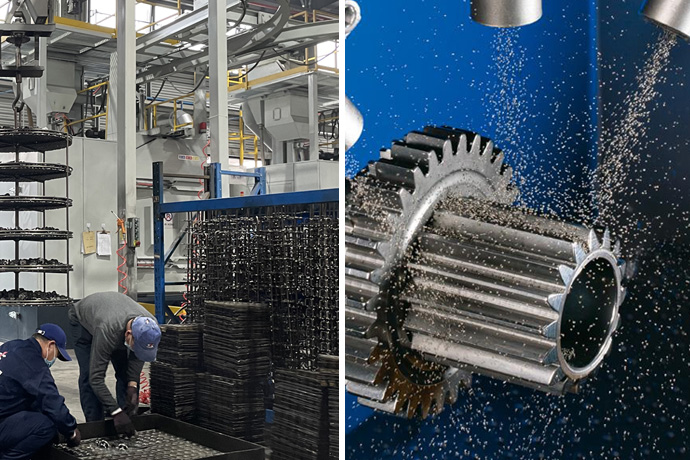

Heat treatment

Multipurpose furnace technology for enhanced performance

Our heat treatment process uses a multifunctional heat treatment furnace that can perform a variety of heat treatment processes such as annealing, normalizing, quenching and tempering. This flexibility not only improves processing efficiency, but also ensures that the mechanical properties of each product meet or exceed customer requirements.

Surface treatment

Sand blasting, perfect surface quality

Through advanced sandblasting technology, we are able to remove impurities from the surface of all workpieces, ensuring a consistent and high-quality surface. This step is crucial to improve the corrosion resistance and aesthetics of the product.

Cleaning and anti-rust

Professional cleaning machine and anti-rust fluid treatment

Our cleaning process uses specialized cleaning machines to ensure that each product is clean and free of any residue before shipment. After cleaning, use special anti-rust liquid for anti-rust treatment, which ensures that the product is in the best condition when it reaches the customer.

Package

Packing and shipping

Each gear is first packaged with meteorological anti-rust paper to ensure that the product does not rust during transportation and storage; it is then packaged in a separate carton to protect the product.

At PairGears, we pride ourselves on our manufacturing capabilities and technological innovation. We don't just settle for industry standards, we aim to define them. When you choose us, you choose quality, precision and superior performance guaranteed.

Quick Quote

Minimum Order for Precision Gears is 1 Piece

Imagine what it would be like to have a place that could bring your ideas to life. PairGears doesn't just provide products, we provide the possibility to make your dreams come true. Every innovation starts with a simple idea, and we're here to help you explore those endless possibilities. Click below to take the first step in your customization journey. Let’s uncover the mystery behind customized services and discover how to turn your unique ideas into concrete practice. Because at PairGears, we believe every idea deserves to be crafted with care.Quick Quote

Partner

Committed to Our Customers

Join Our Distributors

Are you looking for a partnership with huge market potential and generous profit margins? As our distributor, you will receive comprehensive market support, high-quality product resources, and professional business training. Contact us now to learn more about becoming our distributor and start your journey to success!

- Name

- Tel

- *Title

- *Content