Common Problems and Solutions in Gear Replacement

Introduction

Gear replacement is a critical aspect of maintaining the performance and efficiency of mechanical systems, whether in heavy machinery, automotive applications, or precision equipment. Over time, gears wear out due to stress, misalignment, or lack of proper lubrication, making replacements inevitable. However, selecting and installing the right replacement gear comes with its own set of challenges. In this article, we will explore the most common problems encountered during gear replacement and offer solutions to ensure your system runs smoothly. At PairGears, we have extensive experience in providing high-precision, reliable gears tailored to meet various industrial needs.

Common Problems in Gear Replacement

1. Incorrect Gear Sizing and Fitment

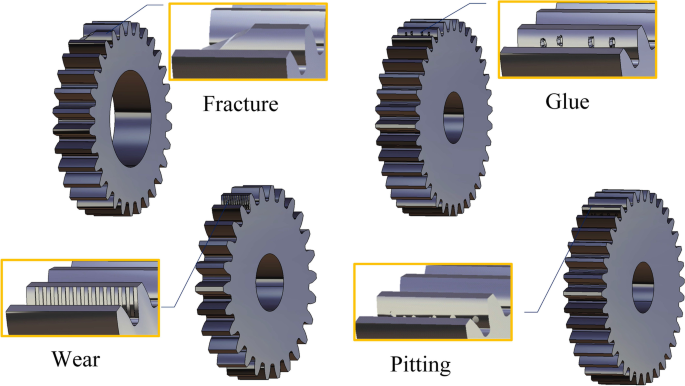

One of the most common issues is selecting a replacement gear that does not fit correctly with the existing gear system. Even minor deviations in gear dimensions, tooth profiles, or materials can lead to performance issues such as increased wear, vibration, and noise.

Solution:

Always ensure that the replacement gear matches the exact specifications of the original gear. If you're unsure of the measurements or specifications, consult a trusted gear manufacturer like PairGears, who can custom-design gears that fit your equipment perfectly. Visit our page for more information on how we ensure precision and accuracy in gear manufacturing.

2. Material Incompatibility

Replacing gears with materials that are not suitable for the application can result in premature wear, failure under load, or reduced system efficiency. For example, using a softer material for a high-load application can lead to rapid gear degradation.

Solution:

Always choose a gear material that matches the demands of the application. At PairGears, we offer a wide range of materials, including high-strength steel, aluminum, and specialized alloys, to ensure that the replacement gear can withstand the operational conditions. For more details on material selection, visit our Material Guide.

3. Improper Gear Alignment

Misalignment during gear replacement can cause excessive stress on gear teeth, leading to uneven wear, increased friction, and even gear failure. Misalignment is often difficult to detect without proper tools or expertise.

Solution:

Use precise alignment tools and procedures during gear installation. If possible, have a professional inspect the alignment after installation. PairGears provides detailed installation guides and offers expert support to ensure proper alignment.

4. Inadequate Lubrication

Lubrication plays a critical role in the lifespan of gears. Inadequate lubrication during or after gear replacement can result in excessive friction, leading to overheating and accelerated wear.

Solution:

Ensure that the gear system is properly lubricated after replacement. Using high-quality lubricants is essential, and regular maintenance should be conducted to check lubrication levels. Visit our page for recommendations on lubrication and maintenance practices.

5. Failure to Address the Root Cause of Gear Failure

Replacing a gear without investigating why the original gear failed can lead to repeated failures. Common causes of gear failure include overloading, improper maintenance, or environmental factors such as excessive heat or contamination.

Solution:

Conduct a thorough investigation of the failed gear to determine the root cause. PairGears offers diagnostic services to help identify underlying issues and recommend improvements. Preventative measures, such as upgrading to more durable materials or better lubrication systems, can extend the life of the replacement gear.

PairGears' Expertise in Gear Replacement

At PairGears, we understand the complexities involved in gear replacement and offer tailored solutions to ensure that your system performs optimally. Our expertise spans across industries such as automotive, agriculture, and heavy machinery. From precision engineering to custom material selection, we help clients overcome the common problems associated with gear replacement.

Explore more about our Gear Manufacturing Process and how we ensure the highest standards of quality in every gear we produce.

Conclusion

Gear replacement is an intricate process that requires careful attention to detail to avoid common pitfalls such as improper sizing, material selection, and misalignment. By following best practices and working with a trusted gear manufacturer like PairGears, you can ensure the longevity and efficiency of your gear-driven systems. For more information on how we can assist with your gear replacement needs, visit our Contact Us page.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.