Detailed Description of Gear Manufacturing Processes - Gear Grinding

Introduction

Gear grinding is a crucial process in the manufacturing of precision gears. This blog provides an in-depth look at gear grinding, its importance in ensuring high-quality gears, the methods and equipment used, and the benefits it brings to gear performance. With insights into our advanced grinding technology at PairGears, we demonstrate our commitment to excellence in gear manufacturing.

The Importance of Gear Grinding

Gear grinding plays a vital role in the gear manufacturing process for several reasons:

1.Precision: Grinding allows for the creation of gears with extremely tight tolerances, which is essential for applications requiring high accuracy.

2.Surface Finish: The grinding process produces a superior surface finish, which reduces friction and wear, leading to longer gear life.

3.Noise Reduction: Smooth gear surfaces help in reducing noise and vibration during gear operation, which is crucial in automotive and industrial applications.

Gear Grinding Methods

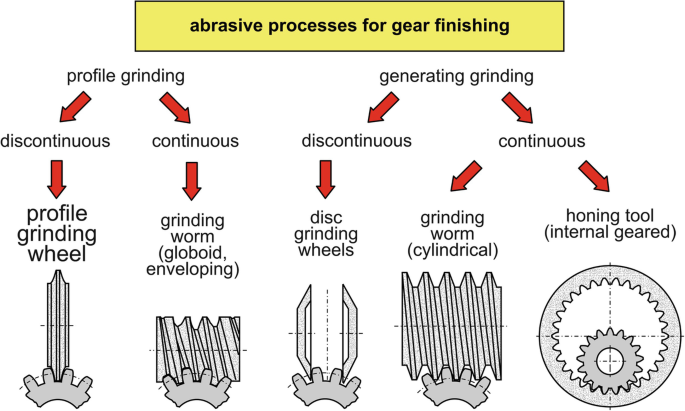

There are two methods used in gear grinding, each with its own advantages:

1.Profile Grinding: This method uses a grinding wheel that is shaped to match the gear tooth profile. It is highly accurate and efficient for high-volume production.

2.Generating Grinding: In this method, the grinding wheel moves along the gear teeth, generating the correct profile as it goes. It is suitable for complex gear geometries and is highly flexible.

Equipment Used in Gear Grinding

At PairGears, we use the latest gear grinding machines, such as:

1.Reishauer RZ Series: Known for its precision and efficiency, this machine allows for the grinding of high-quality gears with minimal setup time.

2.Gleason Phoenix 280G: This machine is versatile and capable of grinding a wide range of gear types, from spur gears to helical gears.

Benefits of Advanced Gear Grinding

Our advanced grinding capabilities at PairGears offer several benefits:

1.High Precision: Our grinding machines ensure that each gear meets exact specifications.

2.Consistent Quality: Automated grinding processes ensure uniformity across large production runs.

3.Enhanced Performance: High-quality surface finishes improve gear performance and longevity.

Conclusion

Gear grinding is a critical step in the gear manufacturing process that ensures the production of high-quality, precise gears. At PairGears, our investment in advanced grinding technology reflects our dedication to excellence in gear production.