Efficiency Redefined: The Power of Gear Hobbing in Modern Manufacturing

Introduction

Gear hobbing is a highly efficient and precise method for manufacturing gears, commonly used in various industries, from automotive to aerospace. At PairGears, we specialize in delivering top-notch gear hobbing solutions to meet your specific needs. In this blog, we'll delve into the process of gear hobbing, its advantages, and why it's a preferred choice for gear manufacturing.

What is Gear Hobbing?

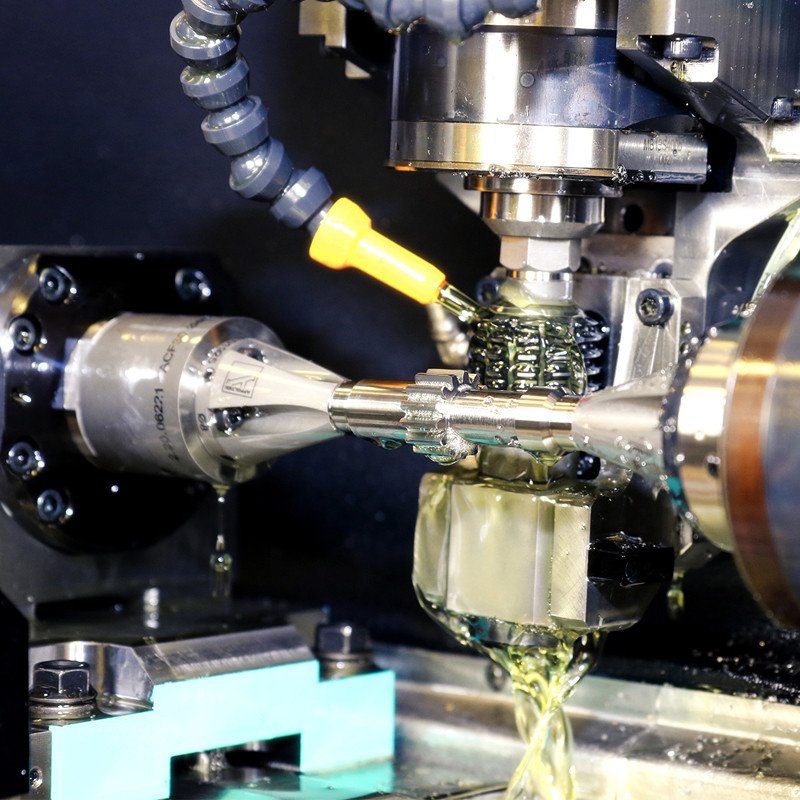

Gear hobbing is a machining process for creating gear teeth by using a specialized tool called a hob. The hob cuts into the blank gear material, progressively shaping it into the desired gear profile. This method is known for its versatility and ability to produce gears with high accuracy and consistency.

Advantages of Gear Hobbing

1.Precision: Gear hobbing offers exceptional precision, producing gears with tight tolerances and consistent quality.

2.Efficiency: The process is highly efficient, capable of manufacturing large quantities of gears quickly.

3.Versatility: It can be used to create a wide variety of gear types, including spur gears, helical gears, and worm gears.

4.Cost-Effective: Due to its speed and precision, gear hobbing is often more cost-effective than other gear manufacturing methods.

Applications of Gear Hobbing

Gear hobbing is used across various industries, including automotive, aerospace, and industrial machinery. It's ideal for producing gears for transmissions, engines, and other critical components where precision and durability are paramount.

Our Gear Hobbing Services

At PairGears, we offer state-of-the-art gear hobbing services, utilizing the latest technology to ensure high-quality results. Our team of experts works closely with clients to understand their requirements and deliver customized solutions.

Why Choose PairGears for Your Gear Hobbing Needs?

1.Advanced Technology:

We use cutting-edge hobbing machines and tools to deliver superior quality gears.

2.Experienced Team:

Our skilled professionals have extensive experience in gear manufacturing.

3.Customer-Centric Approach:

We prioritize our clients' needs, ensuring timely delivery and excellent customer service.

Conclusion

Gear hobbing is an indispensable process in modern manufacturing, offering unmatched precision and efficiency. At PairGears, we are committed to providing top-quality gear hobbing services to meet your specific needs. Contact us today to learn more about how we can help you achieve your gear manufacturing goals.