Enhancing Gear Performance Through Advanced Honing Techniques

Introduction

In the realm of modern machinery, the precision and performance of gears are pivotal to the efficiency and reliability of equipment. As a dedicated manufacturer of high-quality gears, PairGears recognizes the significance of employing advanced finishing techniques to achieve optimal gear performance. One such critical technique is gear honing.

Understanding the Gear Honing Process

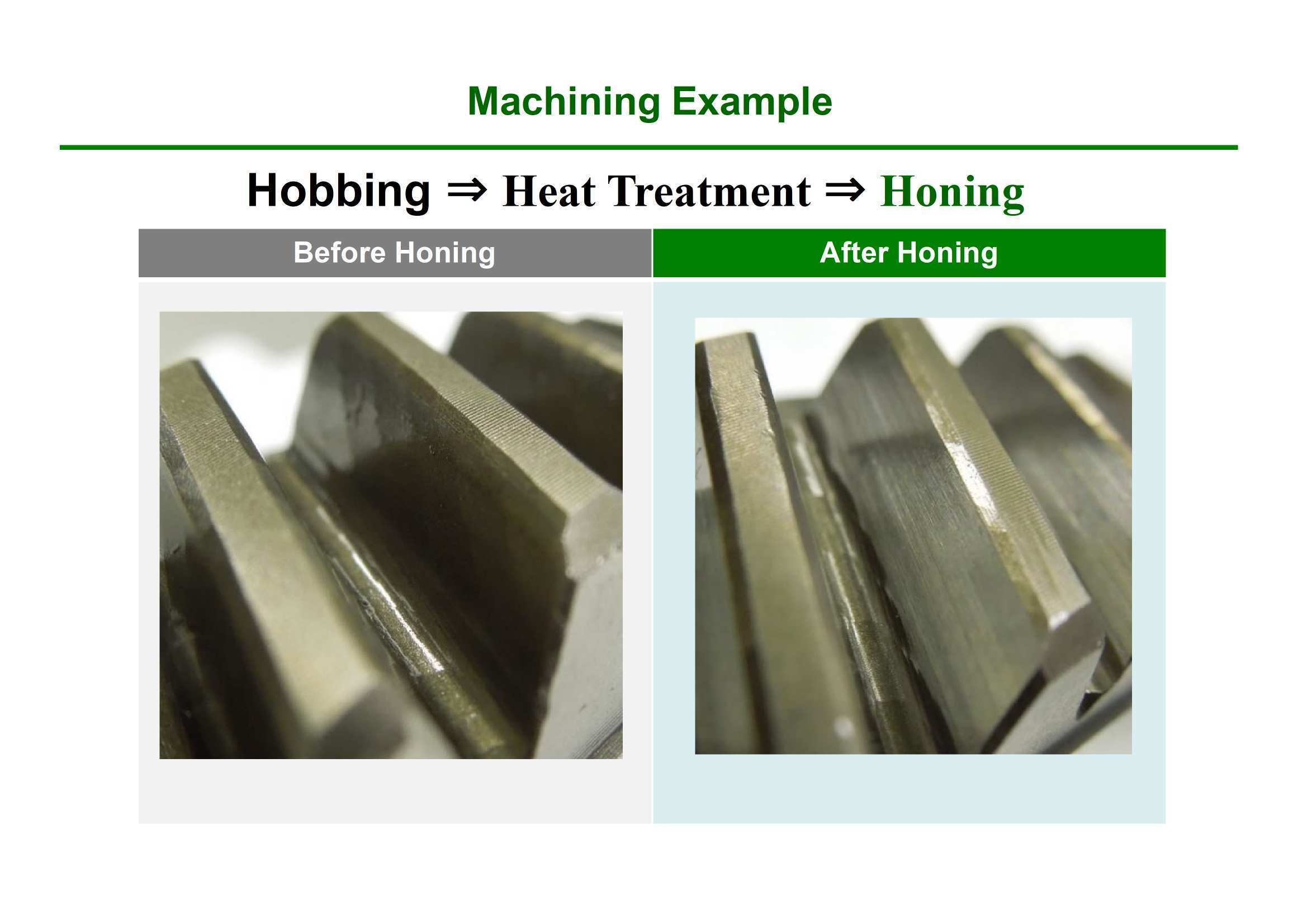

Gear honing is a post-heat treatment finishing process designed to refine the surface quality and precision of gear teeth. Unlike traditional grinding methods, honing operates at lower cutting speeds, typically ranging from 0.5 to 6.5 meters per second, which helps prevent thermal damage to the gear surface. This process effectively corrects tooth profile errors and enhances gear accuracy, often achieving DIN 5 standards. The resultant surface finish can reach roughness levels below Ra 0.2 micrometers, approaching a mirror-like quality.

Advantages of Gear Honing

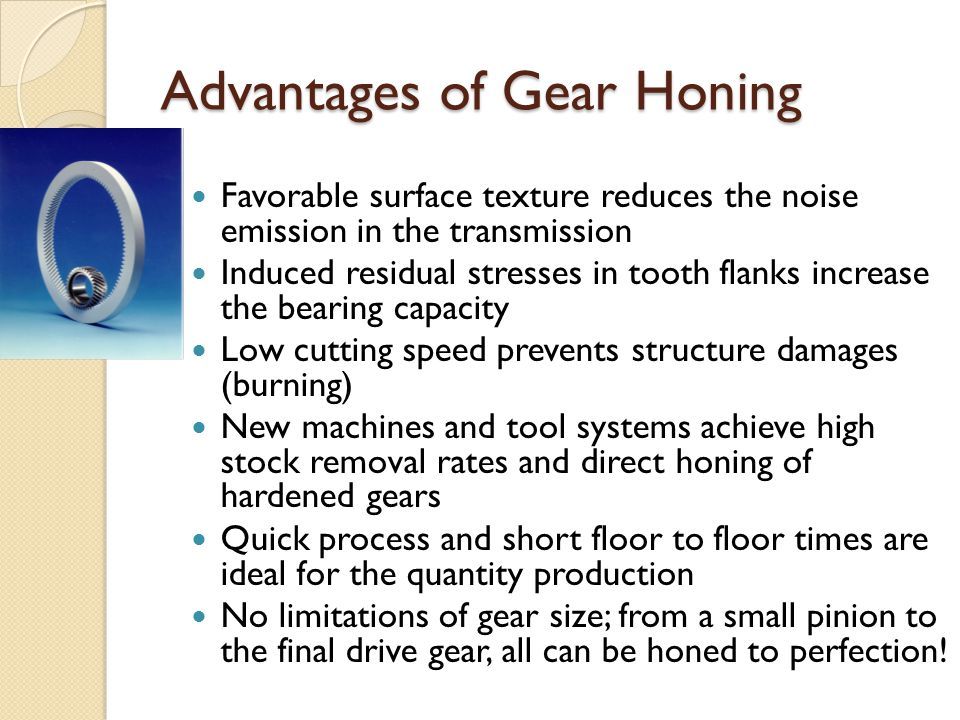

Implementing gear honing in the manufacturing process offers several notable benefits:

• Noise Reduction: The honing process imparts a characteristic curved pattern on the gear surface, facilitating the formation of a lubricating oil film during operation. This reduces vibration and noise in gear transmissions.

• Extended Gear Lifespan: Honing introduces residual compressive stress on the gear teeth surfaces, enhancing wear resistance and prolonging the operational life of the gear.

• Precision in Complex Gear Geometries: Honing is particularly effective for finishing gears with shoulders or intricate profiles, addressing challenges that traditional grinding methods may encounter.

Application of Honing in PairGears Manufacturing

At PairGears, we integrate honing into our production workflow to ensure each gear meets stringent quality and performance criteria. Our approach includes:

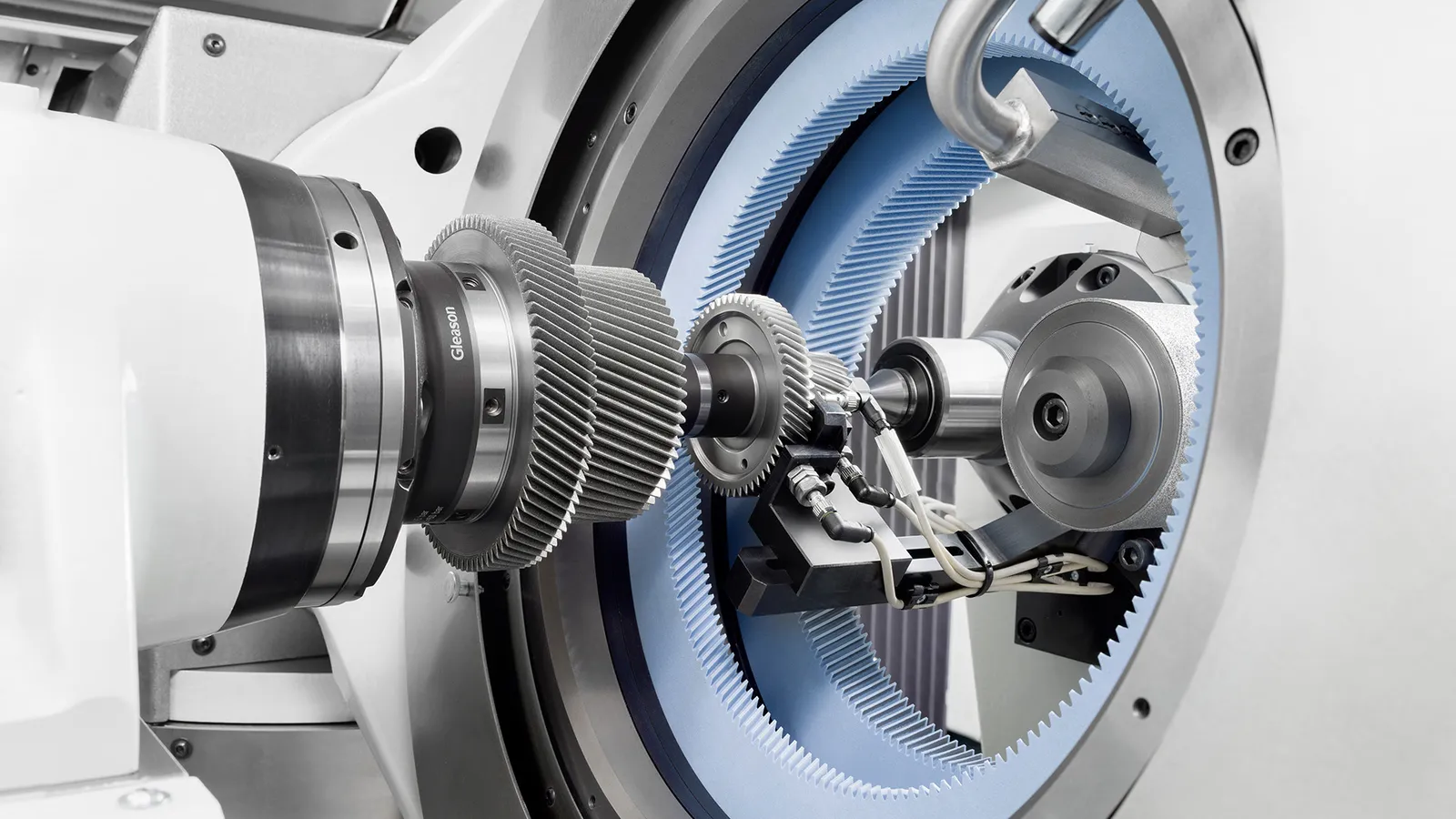

• State-of-the-Art Equipment: Utilizing advanced honing machines to maintain consistency and precision in the finishing process.

• Expert Technicians: Employing skilled professionals who meticulously oversee the honing process, ensuring each gear attains the desired specifications.

• Comprehensive Quality Control: Conducting rigorous inspections post-honing to verify that each gear adheres to both design requirements and industry standards.

Conclusion

Gear honing stands as an indispensable finishing technique, crucial for enhancing gear performance, minimizing noise, and extending service life. At PairGears, our commitment to advanced manufacturing processes ensures that we deliver gears of the highest quality, tailored to meet the diverse needs of various industrial applications.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.