Enhancing Gear Precision: The Gear Lapping Process at PairGears

Introduction

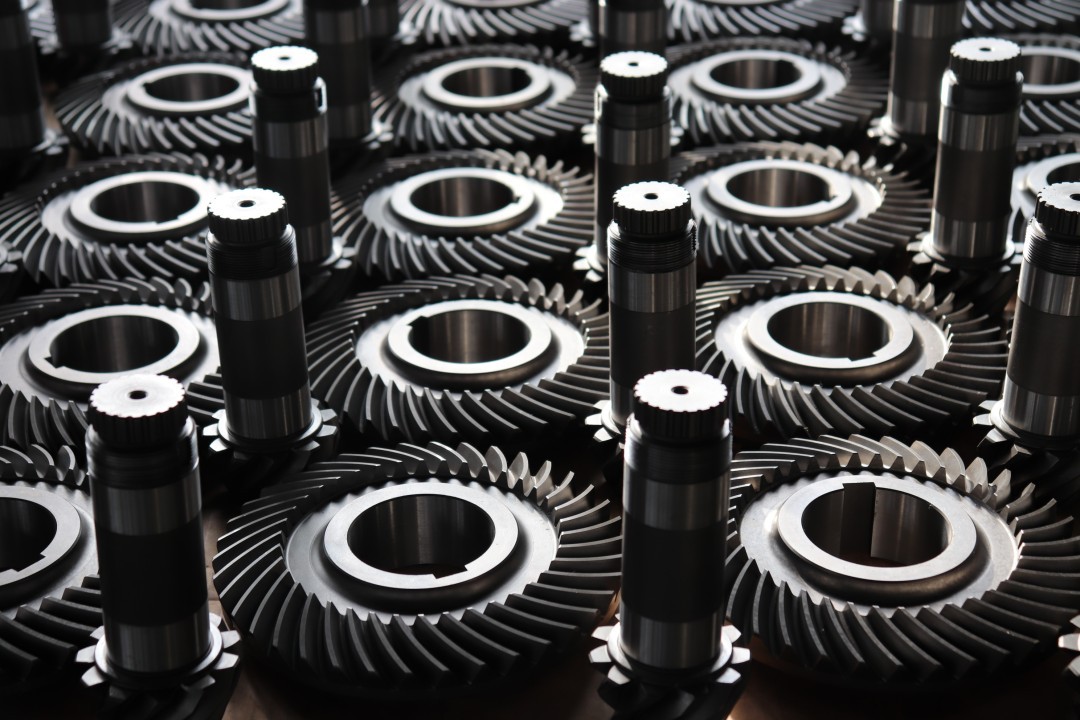

At PairGears, we specialize in manufacturing high-quality gears that meet the rigorous demands of various industries. Our commitment to excellence drives us to employ advanced manufacturing processes, including precision gear lapping, to ensure optimal performance and longevity of our products.

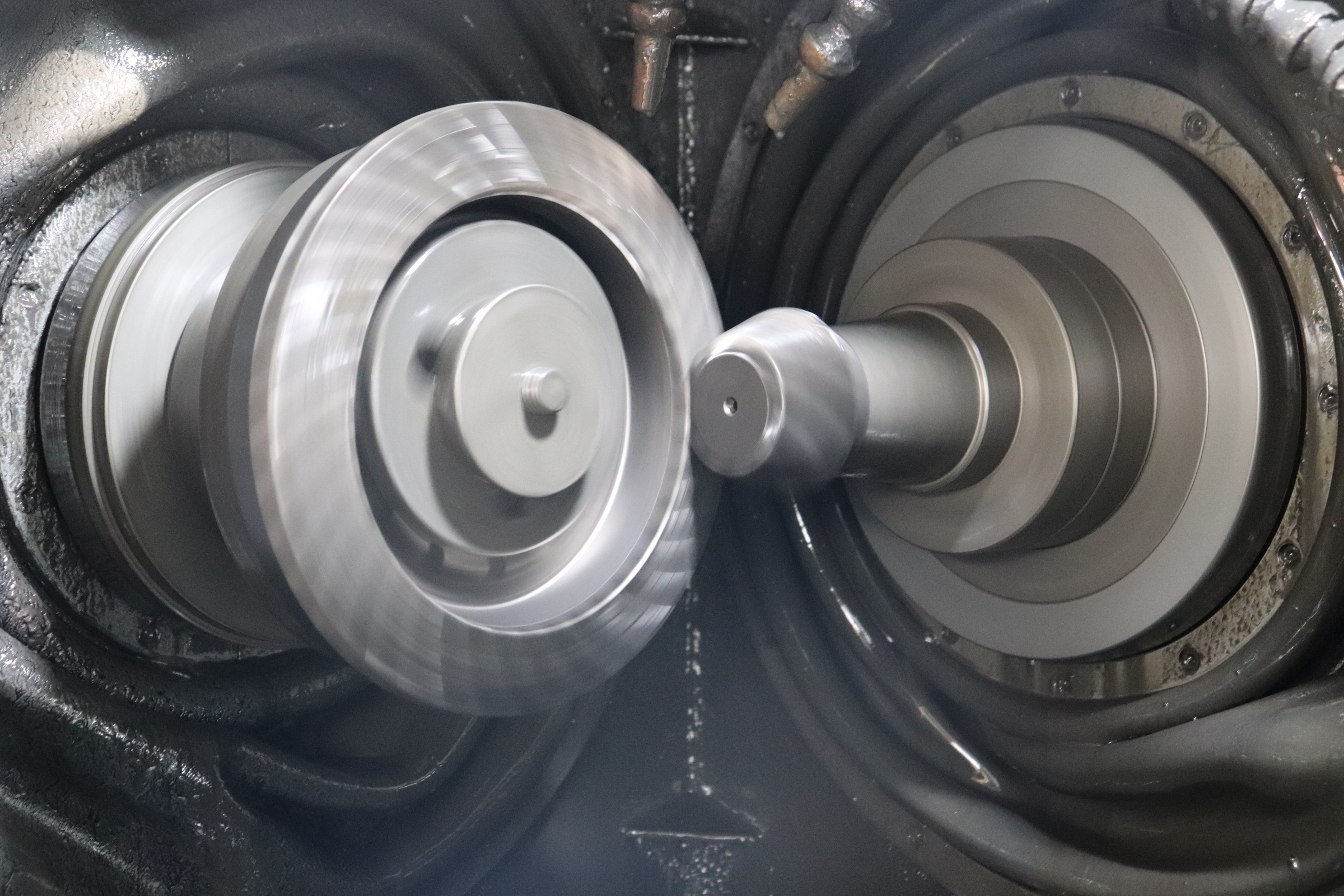

Understanding the Gear Lapping Process

Gear lapping is a finishing technique used to improve the surface quality of gear teeth after initial manufacturing. This process involves the use of a lapping tool and an abrasive compound to polish the gear teeth, resulting in smoother surfaces and enhanced gear meshing. The primary objectives of gear lapping include:

1. Surface Refinement: Achieving a high-quality finish that reduces friction and wear.

2. Noise Reduction: Enhancing the contact pattern between gear teeth to minimize operational noise.

3. Accuracy Improvement: Correcting minor deviations in tooth geometry to ensure precise gear engagement.

Advantages of Gear Lapping

Implementing gear lapping in the manufacturing process offers several benefits:

• Improved Surface Finish: Lapping produces exceptionally smooth tooth surfaces, which contribute to reduced friction and enhanced efficiency.

• Enhanced Load Distribution: By refining the contact surfaces, lapping promotes uniform load distribution across gear teeth, extending the lifespan of the gear.

• Reduced Operational Noise: Smoother gear surfaces result in quieter operation, a critical factor in applications where noise reduction is essential.

Considerations in Gear Lapping

While gear lapping offers notable advantages, it is important to consider certain factors:

• Material Removal Rate: Lapping removes a minimal amount of material, making it unsuitable for correcting significant tooth profile errors.

• Process Efficiency: Although effective, lapping can be time-consuming and may not be ideal for high-volume production without appropriate automation.

• Applicability: Lapping is typically employed for fine-tuning and is most beneficial for gears requiring high precision and smooth operation.

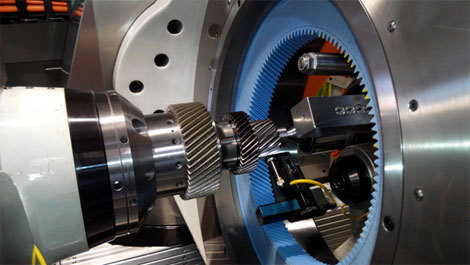

PairGears' Expertise in Gear Lapping

At PairGears, we integrate precision lapping into our manufacturing process to deliver gears that meet stringent quality standards. Our skilled technicians utilize state-of-the-art equipment to perform lapping operations that enhance gear performance across various applications. Whether for automotive, industrial machinery, or specialized equipment, our lapped gears provide the reliability and efficiency our clients expect.Click to explore our gear manufacturing!

Conclusion

Gear lapping is a vital finishing process that significantly enhances the performance and durability of gears. By improving surface finish and ensuring precise tooth geometry, lapping contributes to quieter, more efficient gear operation. At PairGears, we are dedicated to employing advanced techniques like gear lapping to produce superior gears tailored to our clients' specific needs.

For more information on our gear manufacturing capabilities or to discuss your specific requirements, please contact us today!

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.