How to Replace Gears to Extend Equipment Lifespan?

Introduction

Gears play a vital role in the smooth operation of various types of machinery, from industrial equipment to automotive systems. Over time, gears can experience wear and tear, affecting their performance and potentially leading to equipment failure. Proper gear replacement is essential to maintain the efficiency and extend the lifespan of your equipment. In this blog, we'll guide you through the steps of effective gear replacement and highlight the benefits of doing it correctly.

Understand the Need for Gear Replacement

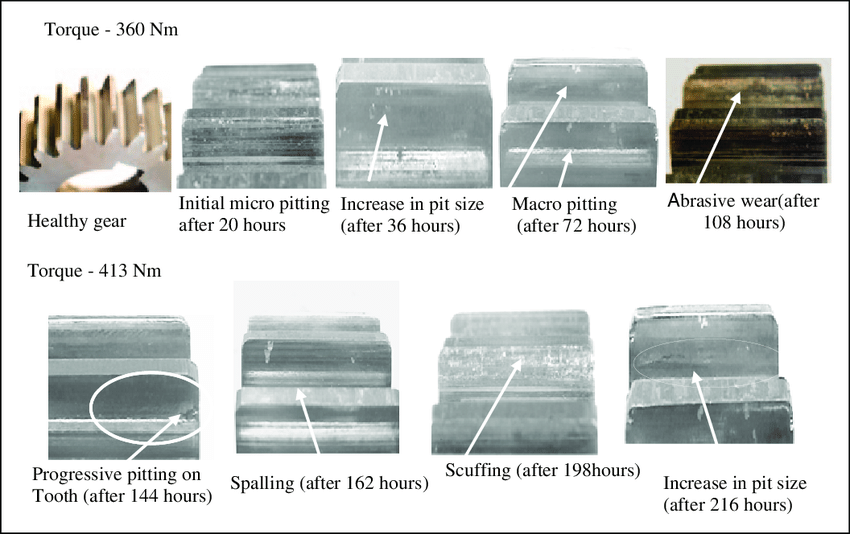

Before replacing a gear, it’s important to recognize the signs that indicate a replacement is needed. Common signs include unusual noise, vibrations, reduced performance, or visible wear on the gear teeth. Regular inspections and maintenance can help identify these issues early.

Choose the Right Replacement Gear

Selecting the correct replacement gear is crucial for ensuring compatibility and performance. When choosing a replacement, consider the following factors:

•Gear Specifications: Match the specifications of the replacement gear with the original, including size, tooth count, and material.

•Material Quality: Opt for high-quality materials that can withstand operational stresses and extend gear life.

PairGears offers a wide range of gears designed to meet rigorous standards. Visit our gear catalog to find the right gear for your needs.

Our customized precision gears can perfectly match these brand equipment, and you can replace them with confidence,more brand replacement gears are in development...

Follow Proper Replacement Procedures

Correctly replacing gears involves several steps:

•Preparation: Ensure that you have the correct tools and replacement parts before starting the process.

•Removal: Carefully remove the worn gear, taking care not to damage surrounding components.

•Installation: Install the new gear, ensuring proper alignment and secure fitting.

If you become our client, PairGears provides comprehensive technical support and training for installation, maintenance, and debugging, making your usage and maintenance process more efficient, for more information, please visit our Service page for repairers.

Test and Verify

After replacing the gear, it's important to test the equipment to ensure everything is functioning correctly. Check for any unusual noises or vibrations and verify that the gear is properly aligned.

Conclusion

To maximize the lifespan of your new gear, schedule regular maintenance and inspections. This proactive approach helps detect potential issues early and prevents premature wear.

Replacing gears correctly is essential for maintaining the performance and extending the lifespan of your equipment. By following the steps outlined in this blog, from recognizing the need for replacement to proper installation and regular maintenance, you can ensure that your machinery operates efficiently and lasts longer. For more information on our gear products and replacement services, visit PairGears's page.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.