The Role of Heat Treatment in Enhancing Gear Performance and Durability

Introduction to PairGears

At PairGears, we specialize in manufacturing high-performance gears for agricultural machinery, trucks, industrial equipment, and more. With a strong commitment to quality and precision, our gears are designed to meet the specific needs of each customer, ensuring optimal performance and longevity. Our website offers detailed product information, and we are dedicated to helping you find the right gear solutions tailored to your requirements.

Now, let's dive into one of the most important aspects of gear design: gear ratios.

What Are Gear Ratios?

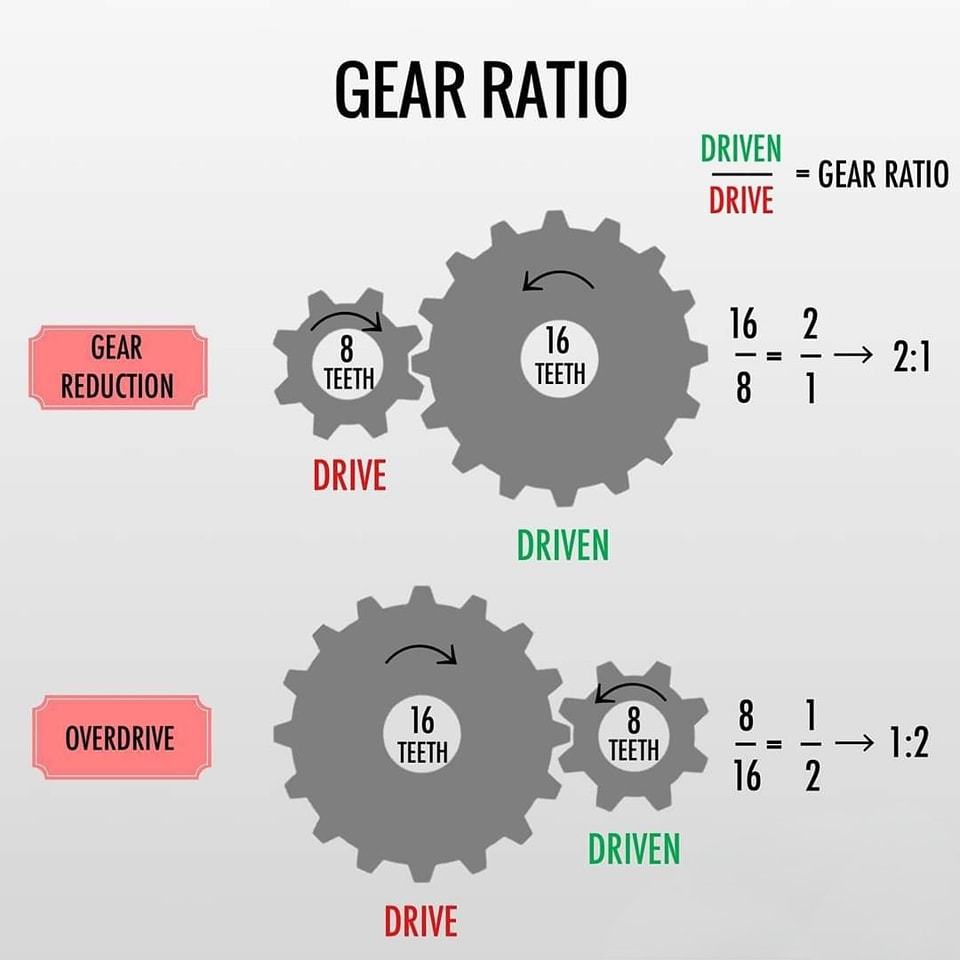

A gear ratio is the ratio of the number of teeth on two meshing gears. It determines how the rotational speed and torque are transmitted between the gears in a gear system. Gear ratios are essential for adjusting the speed and power output of machines, and they play a significant role in the efficiency and functionality of mechanical systems.

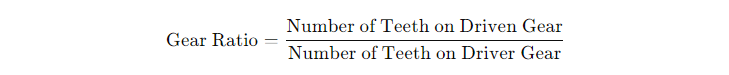

The formula for calculating gear ratio is simple:

In a gear system, the driver gear is the one that initiates the motion, while the driven gear follows the motion of the driver gear. The gear ratio indicates how many times the driver gear must rotate to rotate the driven gear once.

Why Are Gear Ratios Important?

Gear ratios have a direct impact on the performance of a mechanical system. Depending on the application, different gear ratios are used to achieve the desired balance between speed and torque. Here's why gear ratios are crucial:

1. Speed Control

A high gear ratio results in faster speed output, which is ideal for applications that require high rotational speed, such as in small engines and high-speed machinery. On the other hand, a lower gear ratio produces higher torque, which is useful for heavy-duty applications, such as trucks and construction equipment.

2. Torque Transmission

Gear ratios are also crucial in adjusting the torque applied to a system. A lower gear ratio (with fewer teeth on the driven gear) increases torque, while a higher gear ratio (with more teeth on the driven gear) reduces torque. This is why gear ratios are often carefully selected based on the power requirements of a given application.

3. Efficiency Optimization

By selecting the right gear ratio, manufacturers can ensure that machinery operates at its highest efficiency. A well-chosen gear ratio can minimize energy losses and reduce the strain on the system, leading to longer lifespan and better overall performance.

4. Mechanical Advantage

Gear ratios also provide a mechanical advantage. In cases where high torque is required, such as lifting heavy loads, a lower gear ratio provides the necessary mechanical advantage to perform the task effectively.

Types of Gear Ratios and Their Applications

Different gear systems utilize various gear ratios, depending on the desired outcome. Some of the most common types include:

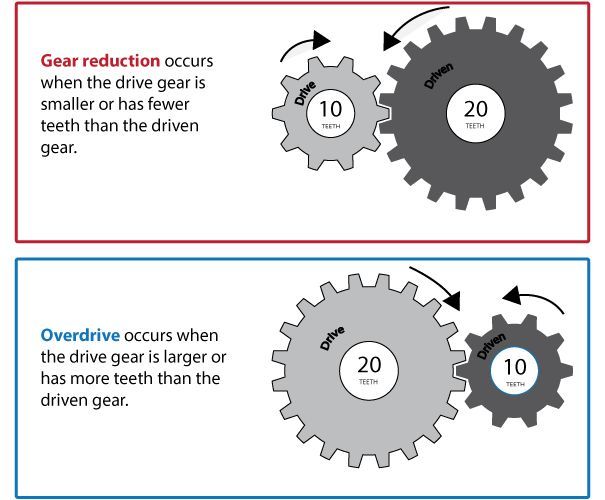

1. Reduction Gear Ratio

In a reduction gear system, the driven gear has more teeth than the driver gear, resulting in a reduction of speed and an increase in torque. This type of gear ratio is commonly used in heavy-duty applications like trucks and construction machinery, where high torque is required to move large loads.

2. Overdrive Gear Ratio

An overdrive gear ratio is used when the driven gear has fewer teeth than the driver gear. This increases speed and decreases torque, which is commonly used in applications like automotive transmissions, where high-speed operation is required, and fuel efficiency is a priority.

3. Direct Drive Gear Ratio

A direct drive ratio occurs when the driver and driven gears are the same size. This provides a 1:1 ratio, meaning the speed of the driver gear equals the speed of the driven gear. This ratio is often used in applications where consistent speed is required, such as in conveyor systems.

How PairGears Implements Gear Ratios

At PairGears, we manufacture a variety of gears with different gear ratios to meet the needs of our clients across multiple industries. Whether it's agricultural machinery, truck transmissions, or industrial equipment, we ensure that our gears are tailored to deliver the optimal balance between speed, torque, and efficiency.

For example, our gears for agricultural machinery may utilize a low gear ratio to provide high torque for tasks like plowing and harvesting, while our gears for automotive applications may feature a high gear ratio for speed and fuel efficiency.

Explore our products for more information on the gear solutions we offer.

How to Choose the Right Gear Ratio

Choosing the right gear ratio depends on the specific requirements of the application. Key factors to consider include:

1. Load Capacity:

Heavy loads require gears with lower ratios for higher torque.

2. Speed Requirements:

High-speed applications need gears with higher ratios for faster rotation.

3. Efficiency:

Choose a gear ratio that minimizes energy loss and ensures the optimal performance of the system.

If you're unsure about which gear ratio is right for your application, PairGears can help. Our team of experts will work with you to find the perfect solution for your needs.

Conclusion

In summary, gear ratios are essential for optimizing the performance of mechanical systems. Understanding gear ratios and selecting the right one for your application ensures that your machinery operates efficiently, reliably, and with the desired balance of speed and torque. At PairGears, we pride ourselves on our expertise in gear manufacturing and our ability to deliver high-quality gear solutions that meet the diverse needs of our customers.

If you're looking for precision gears tailored to your specific requirements, visit our product catalog or contact us today for more information.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.