Understanding Aircraft Fuel Pump Gears: Precision Engineering in Aviation Fuel Systems

Introduction

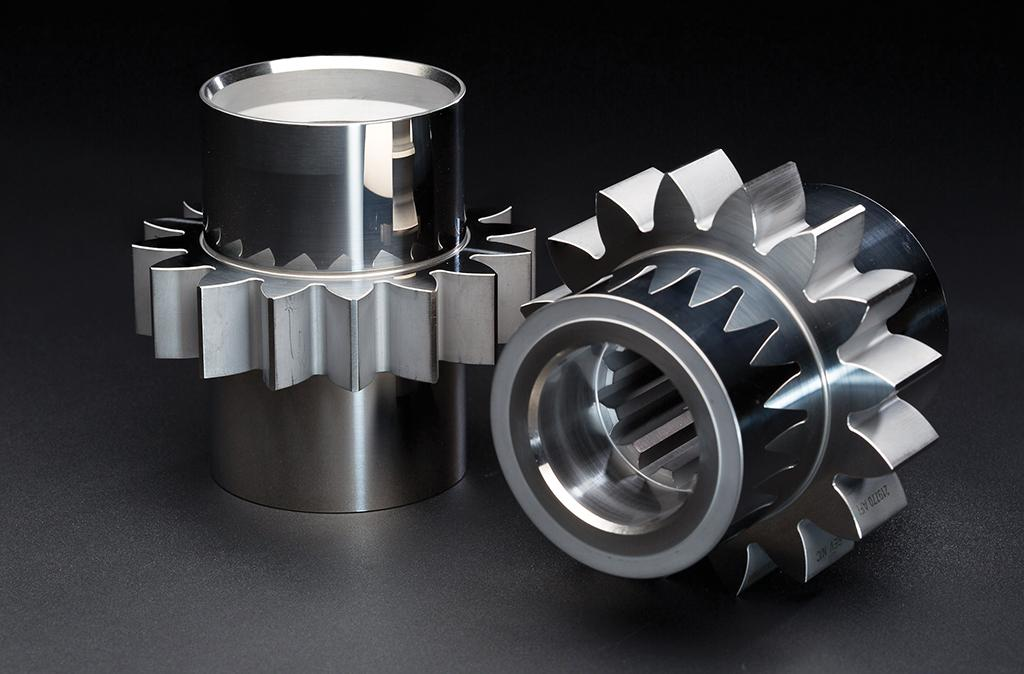

At PairGears, we specialize in producing high-precision gears tailored for demanding applications across agriculture, automotive, industrial machinery, and increasingly, aerospace systems. Among our growing range of aerospace solutions, aircraft fuel pump gears stand out as a critical component in ensuring the safe and reliable delivery of fuel during flight.

In aerospace engineering, where safety, precision, and durability are non-negotiable, the role of the fuel delivery system is paramount. At the heart of this system lies the fuel pump, and within it, the fuel pump gears that drive its performance. These gears are not just mechanical parts—they are precision-engineered components designed to perform flawlessly under extreme conditions. In this article, we explore the function, design, and operational demands of aircraft fuel pump gears, and how they contribute to the performance and safety of modern aviation systems.

What is an Aircraft Fuel Pump Gear?

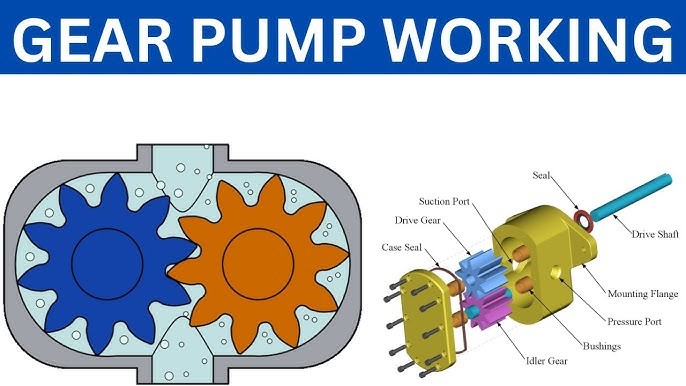

An aircraft fuel pump gear is a precision-engineered component within the fuel pump system, responsible for transferring fuel from the aircraft's tanks to its engines. These gears operate within gear-type fuel pumps, which are positive displacement pumps utilizing the meshing of gears to move fuel efficiently. The design ensures a consistent fuel flow rate, crucial for maintaining engine performance and safety during flight.

Types of Fuel Pumps in Aviation

Aviation fuel systems employ various types of pumps, each suited for specific applications:

• Gear Pumps: Utilize meshing gears to pump fuel, offering durability and efficiency.

• Centrifugal Pumps: Use a rotating impeller to move fuel, suitable for handling large volumes at lower pressures.

• Piston Pumps: Employ a reciprocating piston mechanism, providing precise control over fuel flow.

Among these, gear pumps are widely used in aircraft fuel systems due to their reliability and ability to maintain consistent fuel delivery under varying pressures.

Precision Requirements for Aircraft Fuel Pump Gears

The manufacturing of aircraft fuel pump gears demands exceptional precision to ensure optimal performance and safety:

• Tight Tolerances: Gears must be produced with minimal dimensional variations to ensure proper meshing and efficient fuel transfer.

• Material Selection: Materials like carbon-graphite are often used for bushings within the pump due to their self-lubricating properties and compatibility with aviation fuels.

• Surface Finish: A smooth surface finish reduces friction and wear, extending the gear's operational life.

PairGears employs advanced manufacturing techniques and rigorous quality control to meet these precision requirements, ensuring each gear performs reliably in demanding aerospace environments.

Applications in Modern Aircraft

Aircraft fuel pump gears are integral to various aircraft systems, including:

• Commercial Jets: Ensuring consistent fuel delivery in engines like the CFM-56, commonly used in Boeing 737 and Airbus A320 aircraft.

• Military Aircraft: Providing reliable fuel flow in high-performance fighter jets and transport aircraft.

• Helicopters: Maintaining fuel supply in varying flight conditions and orientations.

The reliability of these gears directly impacts the safety and efficiency of flight operations across various aircraft platforms.

PairGears' Commitment to Excellence

At PairGears, we are dedicated to delivering high-quality aircraft fuel pump gears that meet the exacting standards of the aerospace industry. Our capabilities include:

• Custom Gear Design: Tailoring gear specifications to meet specific aircraft requirements.

• Advanced Manufacturing: Utilizing CNC machining and precision grinding to achieve tight tolerances and superior surface finishes.

• Quality Assurance: Implementing rigorous testing protocols to ensure each gear meets performance and safety standards.

For more information on our products and services, please visit our official website.

Conclusion

Aircraft fuel pump gears are critical components that ensure the reliable delivery of fuel to aircraft engines. Their precision engineering and robust construction are vital for the safety and efficiency of flight operations. PairGears' expertise in manufacturing these gears positions us as a trusted partner in the aerospace industry.

For inquiries or to discuss your specific gear requirements, please contact us.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.

Reference resources: