Understanding Gear Manufacturing Specifications: A Comprehensive Guide

Introduction

Gear manufacturing is a highly specialized process requiring precision and expertise. This blog deciphers the core specifications, materials, and capabilities involved in producing high-quality gears. We will break down essential manufacturing parameters, helping you understand the intricate details behind gear production.

Key Gear Manufacturing Specifications

When it comes to creating gears, every parameter matters. Here is a breakdown of key gear manufacturing specifications:

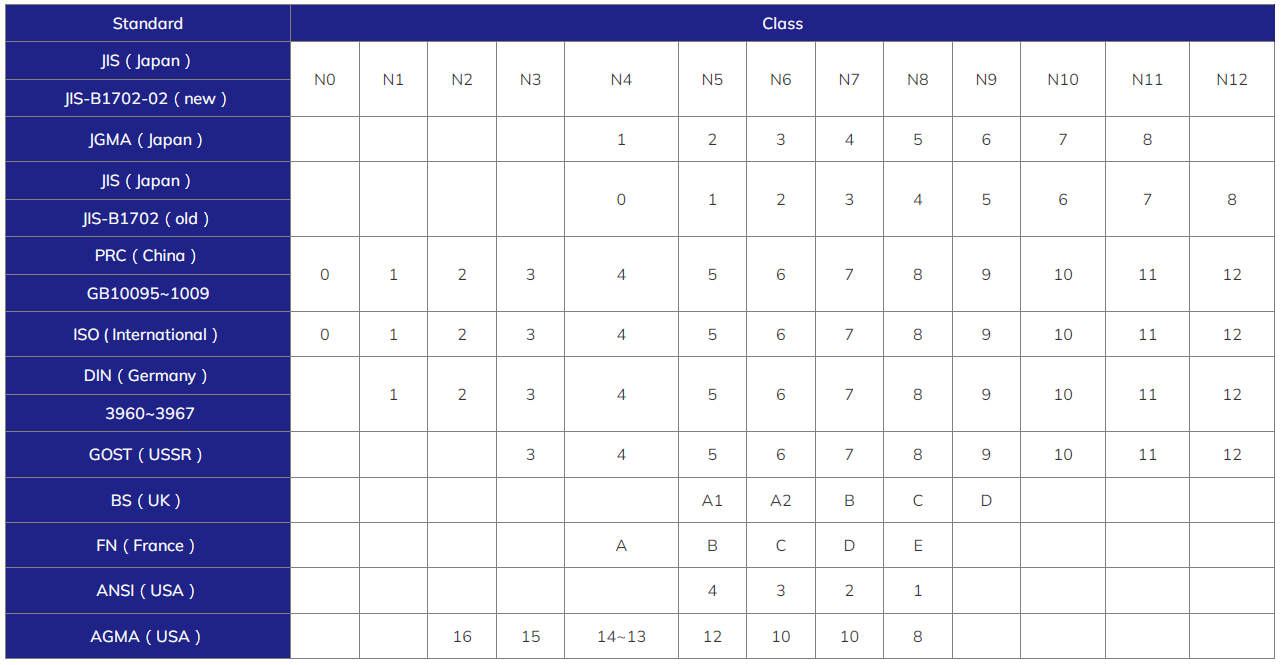

1. Gear Accuracy Standards

Gear precision is vital for smooth and efficient operation. The following table outlines the accuracy standards typically achieved in gear manufacturing:

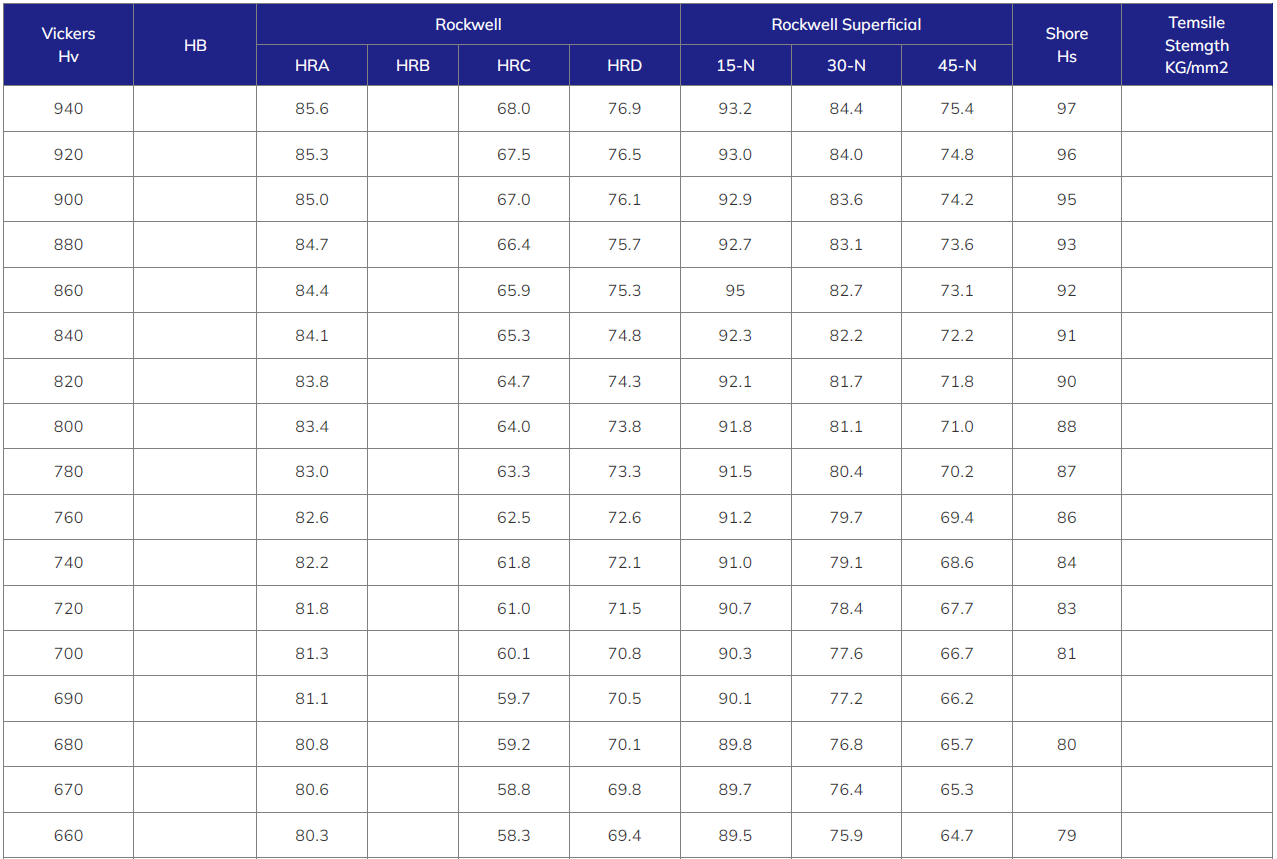

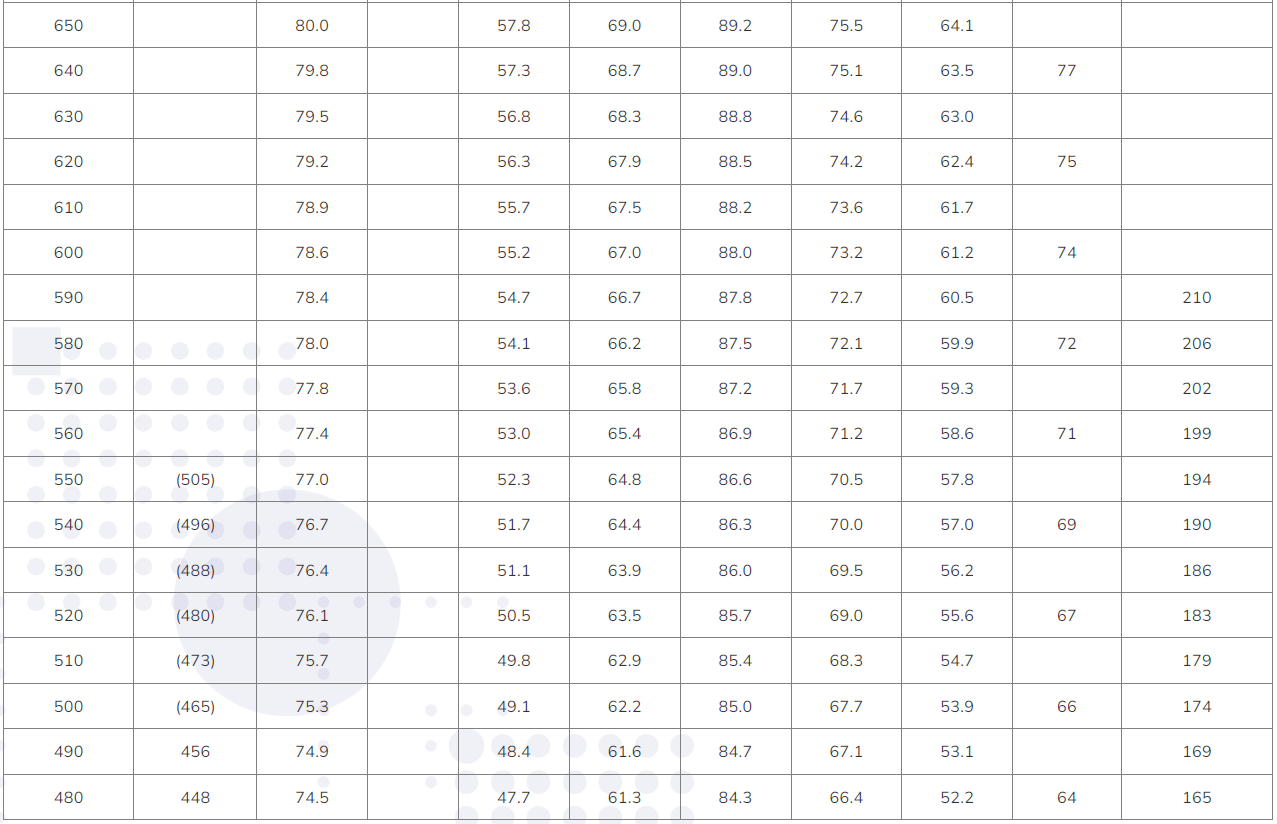

2. Conversion Table of Hardness

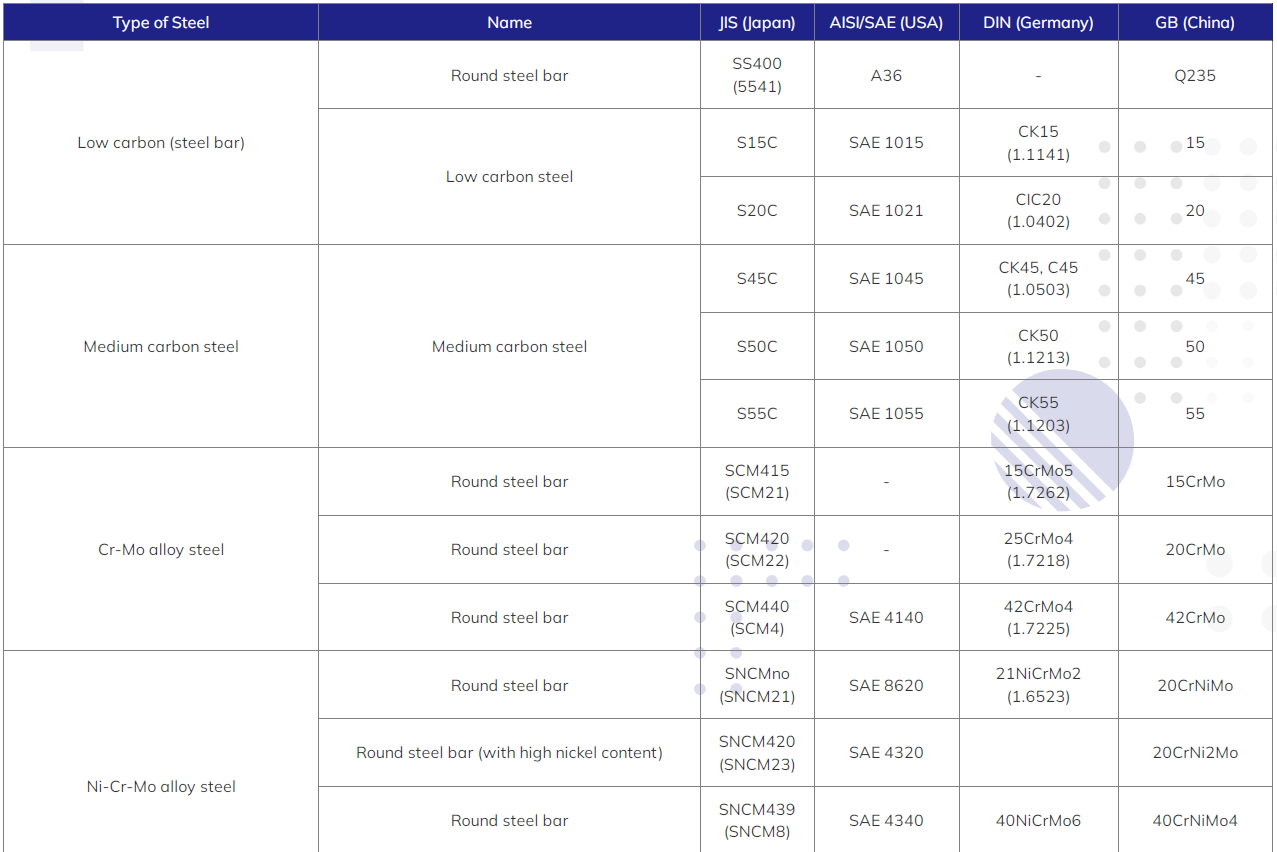

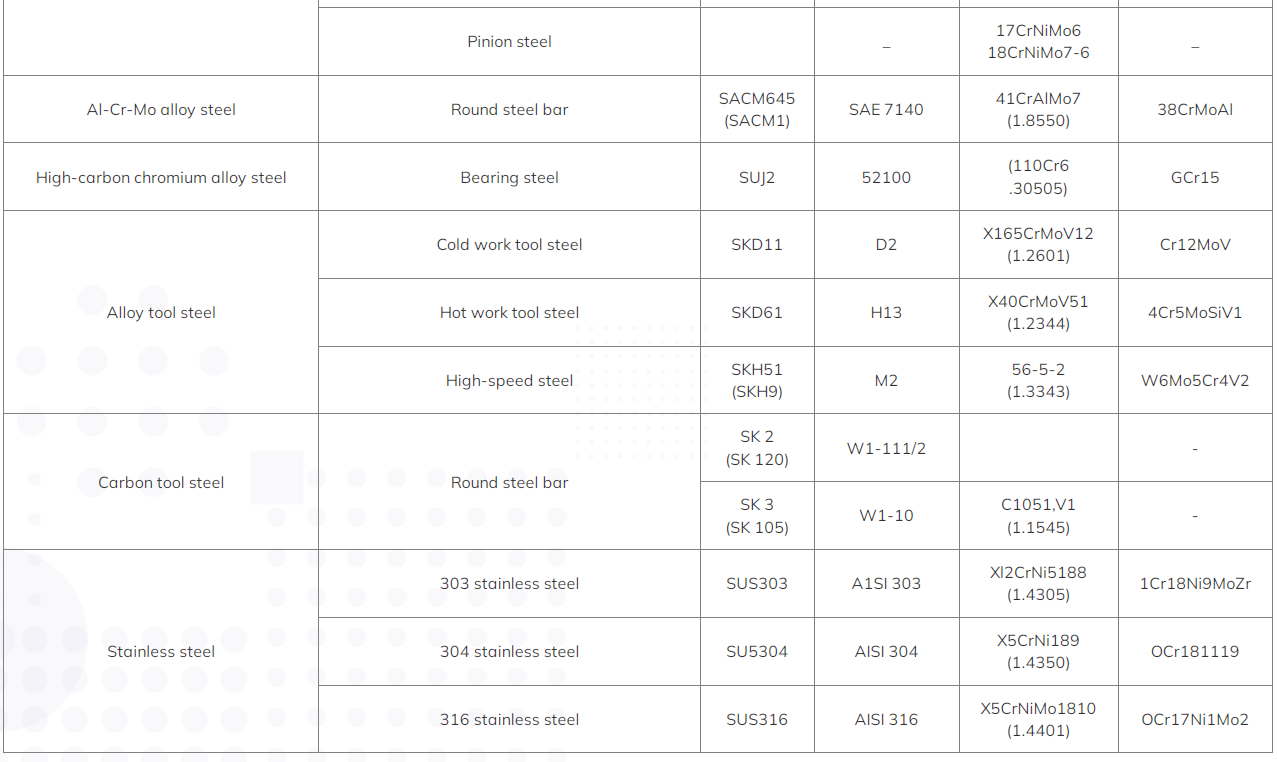

3. Table of Material Properties for Steel

Why Specifications Matter

Every manufacturing specification directly impacts the performance of a gear:

1. Precision Tolerance: Ensures seamless motion and reduced wear.

2. Material Selection: Dictates load capacity and environmental resistance.

3. Surface Treatments: Extends operational lifespan.

At PairGears, we follow stringent manufacturing standards to deliver products suitable for agricultural, automotive, and industrial applications.

Conclusion

Understanding the specifications behind gear manufacturing gives you an edge when choosing components for your machinery. By adhering to standards like AGMA and DIN and leveraging advanced materials and techniques, manufacturers ensure their gears meet the highest industry benchmarks. For more insights on gear manufacturing, visit our Gear Basics Blog or explore our customization options.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.