What is Gear Backlash and Why Does It Matter?

What is Gear Backlash?

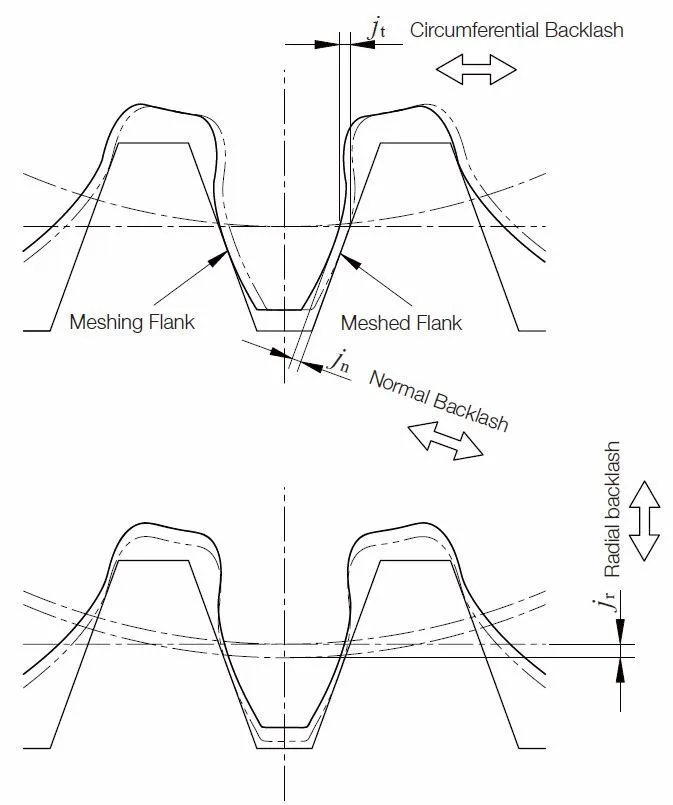

Gear backlash refers to the slight clearance or gap between the mating teeth of two meshing gears. This gap is essential to prevent the gears from binding, but it also introduces a small amount of free play when the direction of rotation is reversed. While necessary to a certain extent, excessive backlash can compromise the gear system’s performance, leading to inefficiencies, noise, and increased wear.

Causes of Gear Backlash

Understanding the causes of gear backlash is crucial for optimizing gear design and performance. Here are the primary factors:

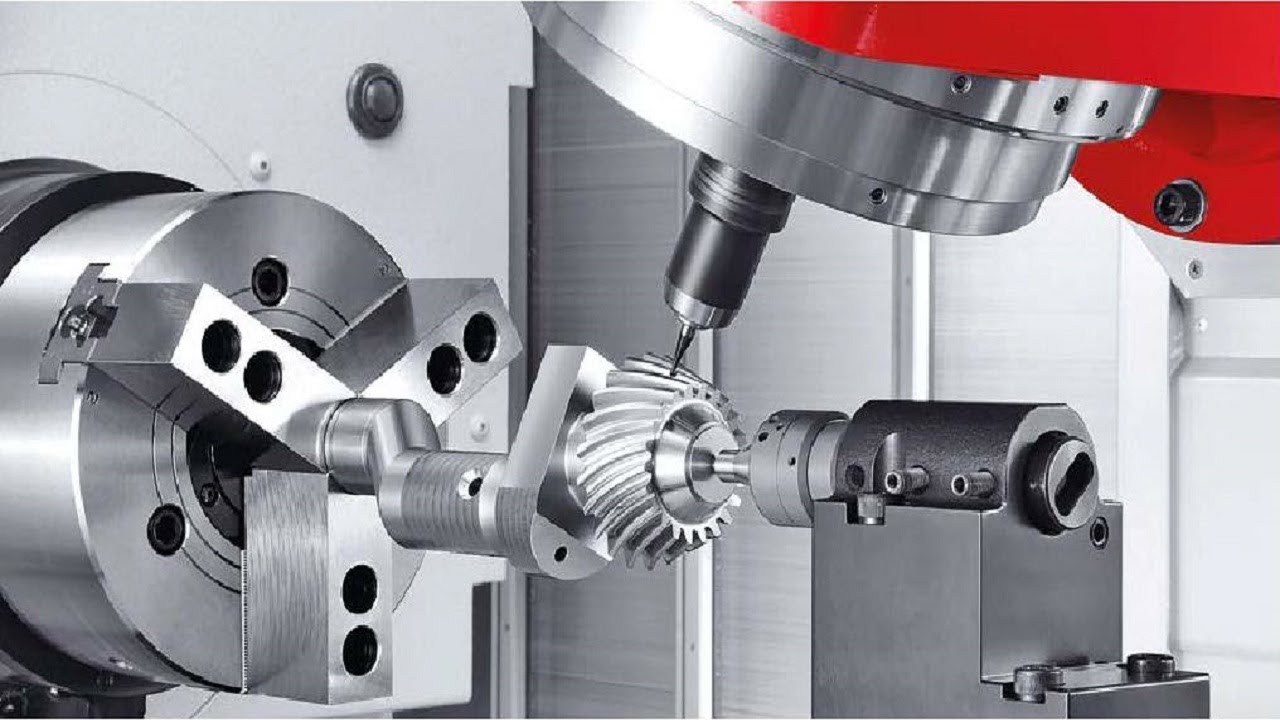

1. Manufacturing Tolerances: Even with precise manufacturing techniques, slight variations in gear tooth dimensions can introduce backlash. At PairGears, we utilize cutting-edge CNC machinery to maintain tight tolerances, ensuring minimal backlash in our gears.

2. Thermal Expansion: Gears are often subjected to varying temperatures during operation, causing them to expand and contract. This thermal expansion can alter the gap between gear teeth, leading to changes in backlash. PairGears uses materials with low thermal expansion coefficients to mitigate these effects.

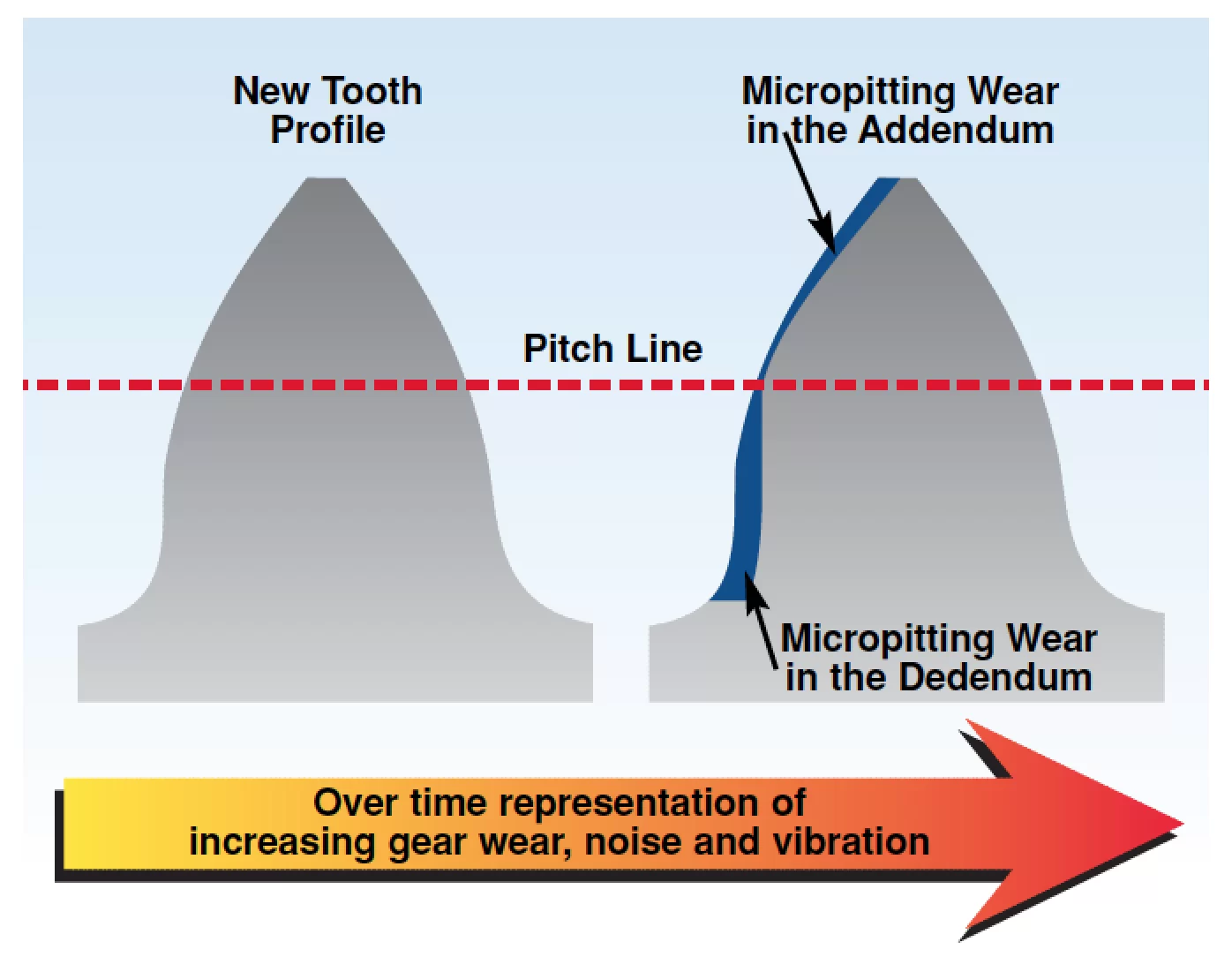

3. Wear and Tear: Over time, gear teeth may wear down due to friction and repeated use, increasing the gap between them and thereby increasing backlash. Regular maintenance and using high-strength materials help reduce wear and extend gear life.

4. Design Considerations: In certain applications, a specific amount of backlash is intentionally designed into the gear system. This allows for thermal expansion, load variations, and slight misalignments. PairGears designs each gear with the precise amount of backlash required for optimal performance, depending on the application.

Impact of Backlash on Gear Performance

The impact of gear backlash on performance can be profound, especially in high-precision applications:

1. Precision and Accuracy: In systems where exact positioning is critical, such as CNC machines and robotics, excessive backlash can lead to positioning errors. This can result in parts being machined inaccurately, leading to product defects. PairGears gears are engineered to minimize backlash, ensuring that machines maintain high levels of precision.

2. Noise and Vibration: Backlash can cause gears to produce unwanted noise and vibrations, especially at high speeds or under heavy loads. In automotive applications, this can lead to uncomfortable driving experiences and potential mechanical issues. PairGears' advanced manufacturing processes help reduce noise and vibration by ensuring gears are finely tuned and precisely aligned.

3. Efficiency and Wear: Excessive backlash increases wear on gear teeth, reducing the efficiency of power transmission. This not only shortens the lifespan of the gears but also reduces the overall efficiency of the system. PairGears uses high-strength, wear-resistant materials to manufacture gears that withstand wear and maintain efficiency over time.

Conversely, insufficient backlash can lead to binding, increased friction, and potential overheating of the gears. Therefore, a proper balance is essential for optimal gear performance and longevity.

How to Minimize Gear Backlash

Minimizing gear backlash is essential for applications that demand high precision and reliability. While backlash is necessary to accommodate manufacturing tolerances, thermal expansion, and lubrication, excessive backlash can lead to inaccuracies, noise, and increased wear. Engineers and designers employ various techniques to mitigate backlash, enhancing the performance and longevity of gear systems.

At PairGears, we understand the importance of minimizing gear backlash to ensure optimal performance and longevity. Our approach includes:

1. Advanced Manufacturing Techniques: We use state-of-the-art CNC machines that allow us to produce gears with minimal tolerances, reducing the risk of excessive backlash.

2. High-Quality Materials: Our gears are made from materials that offer low thermal expansion and high wear resistance, ensuring that backlash remains consistent even under varying operational conditions.

3. Precision Gear Design: Every gear is carefully designed to account for the specific application, ensuring that the backlash is minimized while still allowing for necessary clearances. Whether for industrial machinery, automotive systems, or precision equipment, PairGears delivers gears that meet the highest standards of performance.

For more insights into how we achieve such high precision in our gears, visit our Gear Manufacturing Process page.

Conclusion

In summary, gear backlash is an essential consideration in gear design and manufacturing, influencing the precision, efficiency, and longevity of gear systems. Understanding the causes of backlash, such as manufacturing tolerances, thermal expansion, wear, and design considerations, allows for the development of gears that meet stringent performance requirements. At PairGears, we are committed to minimizing gear backlash through advanced manufacturing techniques, high-quality materials, and precise design practices. Our focus on reducing backlash ensures that our gears perform optimally in various applications, from industrial machinery to automotive systems.

To learn more about this, watch the video on backlash measurement on the right→

You can also refer to the following resources:

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.