Brand Owner Customers

Custom Gear Services for Brand Owner

Brand Owner Customers

Pairgears High-Quality Gear Supply and Customization Services for Brand Owners

Choose Us, And You Will Enjoy the Following Services:

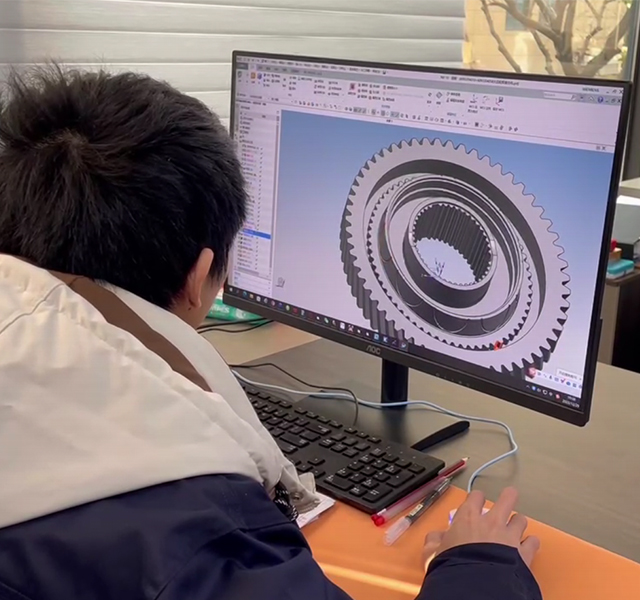

1. Gear Design and Development

The specific content of design and development includes:

1. Structural Design:

Using UG, 3D design software such as Pro/E is used to design gear structures that can achieve precision transmission.

2. Material Selection:

Strictly select suitable materials based on the gear usage environment and strength requirements.

3. Motion Simulation Analysis:

Through precise motion simulation analysis, optimize the gear structure to ensure the optimal transmission efficiency of the gear.

4. Sample Production:

Produce samples based on the selected materials and design drawings.

5. Sample Testing:

Measure whether the size and hardness of the sample meet the design requirements.

6. Trial Installation Verification:

Assist customers in vehicle installation testing and verification of samples.

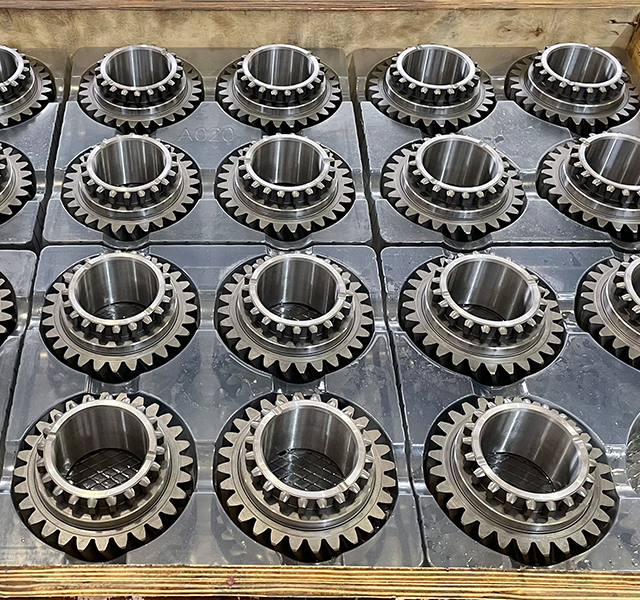

2. Manufacturing and Processing

Core processes of manufacturing and processing include:

1. Forging of Blanks:

High-strength forging processes lay a solid foundation for gears.

2. Lathe Machining:

Fine lathe machining ensures precise gear dimensions..

3. Forming Processes:

Utilizing techniques such as gear hobbing, gear shaping, etc., to achieve precision gear shaping.

4. Heat Treatment:

Through scientific heat treatment processes, we enhance gear hardness and wear resistance.

5. Gear Tooth Grinding:

Achieving excellent surface smoothness and precision for gears.

6. Cleaning and Anti-Rust Treatment:

Ensuring each product is clean and rust-resistant.

3. Customized Production

Customizable contents include:

● Material customization

● Hardness customization

● Dimension customization

● Precision requirement customization

● Exterior color customization

● Package customization

4. Quality Control

Key stages of quality control include:

1. Raw material inspection:

Including strength testing and material composition analysis to ensure the quality of each batch of materials.

2. In-process inspection:

Strict monitoring at every stage of production to ensure precise and accurate processes.

3. Finished product inspection:

Including dimension, hardness, and runout testing to ensure each finished product meets standards.

5. Professional Packaging and Logistics Services

Packaging and logistics services include:

1. Customized packaging:

Providing inner packaging, color box packaging, and transportation packaging according to your needs to build a unique brand image.

2. Logistics services:

Providing sea freight, air freight, and customs clearance services to ensure your products reach their destination smoothly.

Please Lill in Your Information

Understand your business type and specific needs

Provide more targeted product and service recommendations

Tell us about your needs

Your information will be kept strictly confidential and used only to improve our services and to interact with your business. Thank you for your cooperation!

- Customer type

- *Name

- Mobile Phone

Partner

Committed to Our Customers

- *Name

- Mobile Phone

- *Title

- *Content