International Client Visits PairGears Factory, Recognizes Manufacturing Excellence

Introduction

Recently, PairGears had the pleasure of hosting an esteemed client from the international market. The visit aimed to provide the client with a comprehensive understanding of our production capabilities and technical expertise, paving the way for potential collaboration.

In-Depth Product Line Presentation

The visit began with an introduction by the General Manager, who showcased PairGears’ diverse product line. Our solutions, widely used in agricultural machinery, trucks, and construction equipment, sparked significant interest.

The client was particularly impressed by our advancements in gear strength, wear resistance, and surface treatment technologies. A detailed demonstration of product samples further highlighted PairGears’ dedication to innovation and quality.

Factory Tour: Efficiency Meets Quality

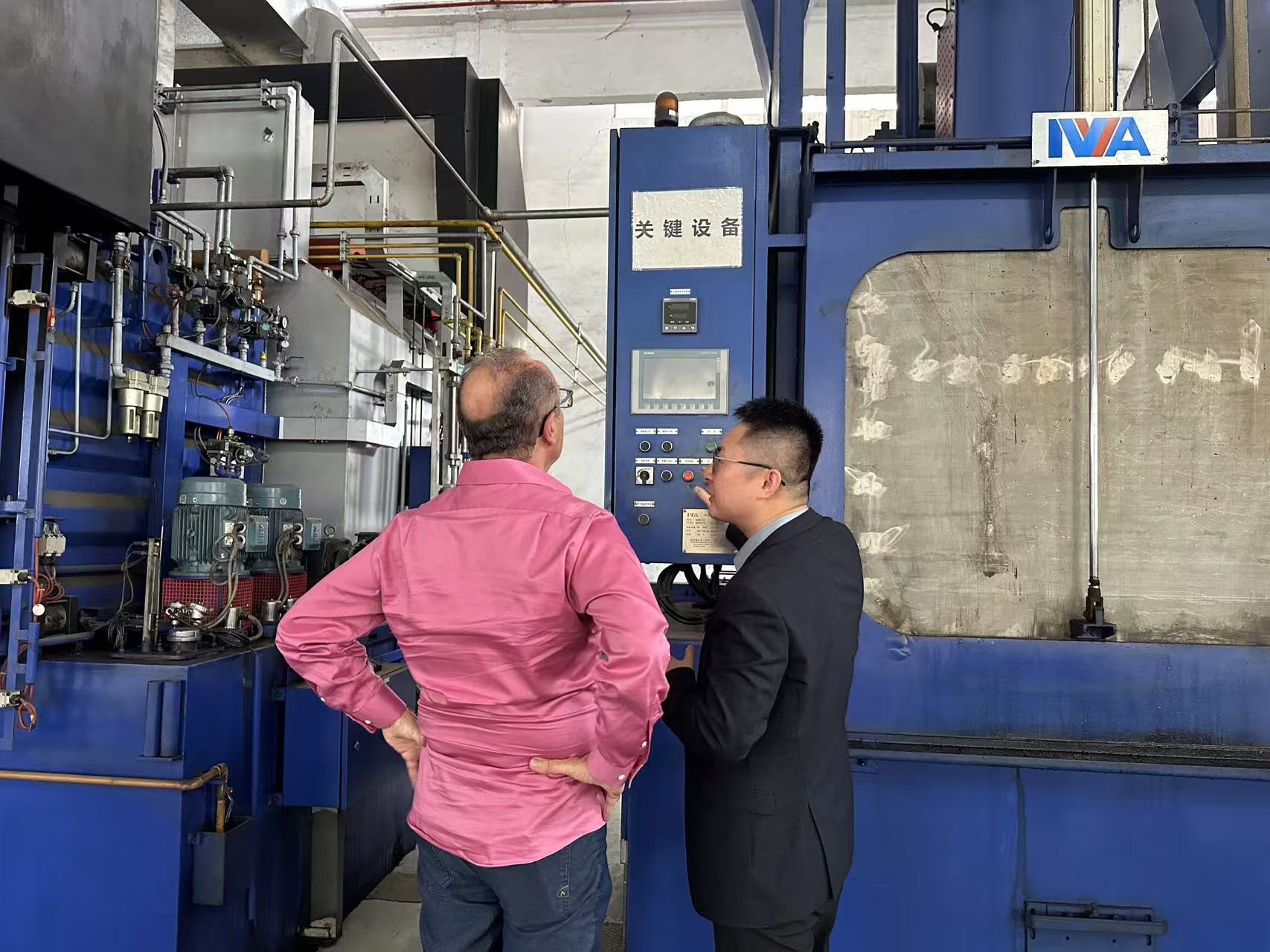

Accompanied by the technical team, the client toured our state-of-the-art manufacturing facility and quality control center. The client observed our cutting-edge CNC machines, five-axis machining centers, and heat treatment equipment in action, gaining insights into our streamlined production processes.

In quality control, PairGears adheres to rigorous international standards. Our advanced testing equipment ensures precision at every stage, from hardness assessments to gear meshing tests. The client praised our commitment to a "zero defect" production philosophy and expressed great confidence in our operational efficiency.

Strengthening Partnerships for the Future

As a leader in gear manufacturing, PairGears operates with the vision of “Driving Growth Through Technology and Excellence.” This visit not only strengthened mutual trust but also set a solid foundation for future cooperation. The client expressed their appreciation for PairGears’ capabilities and looked forward to exploring deeper collaboration opportunities.

About PairGears