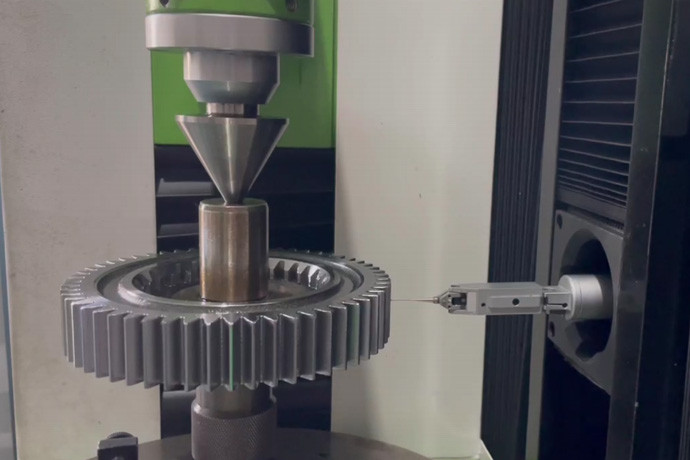

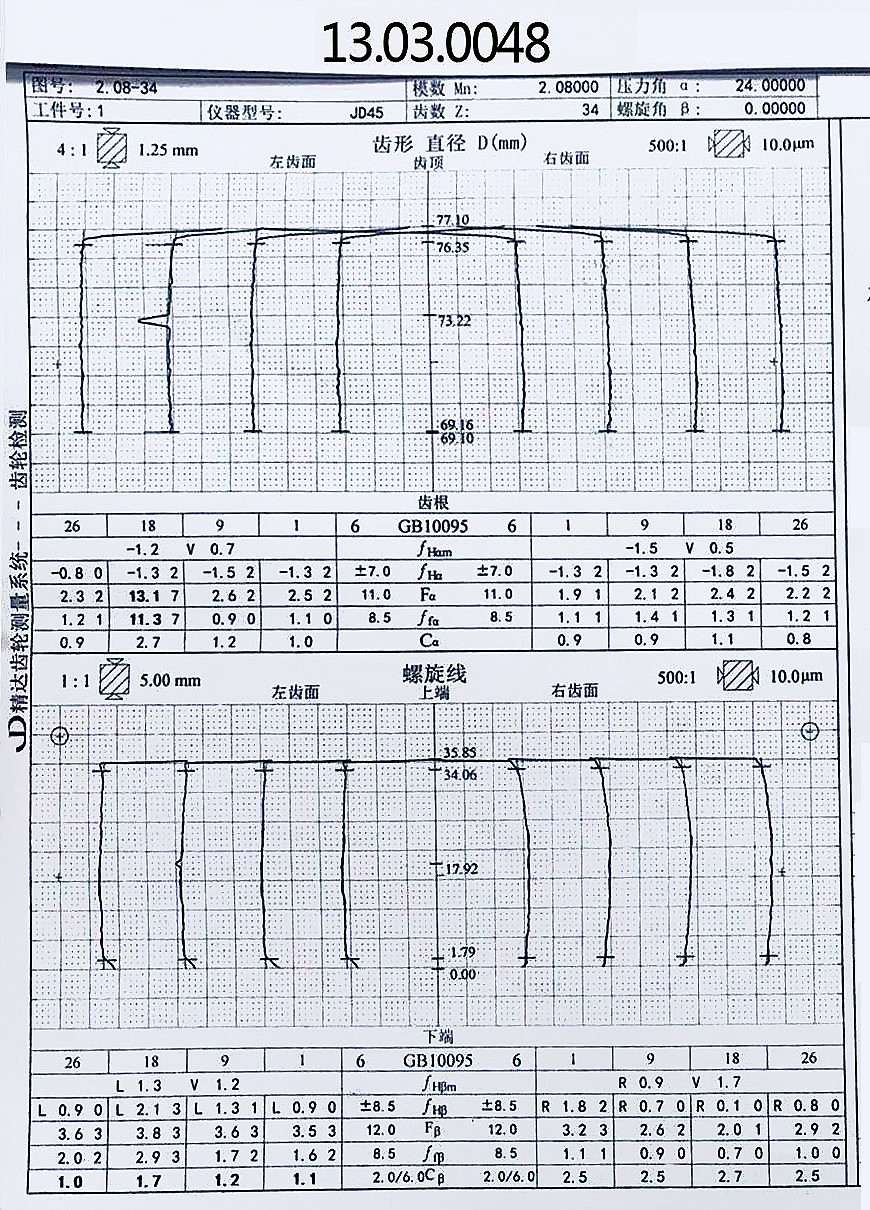

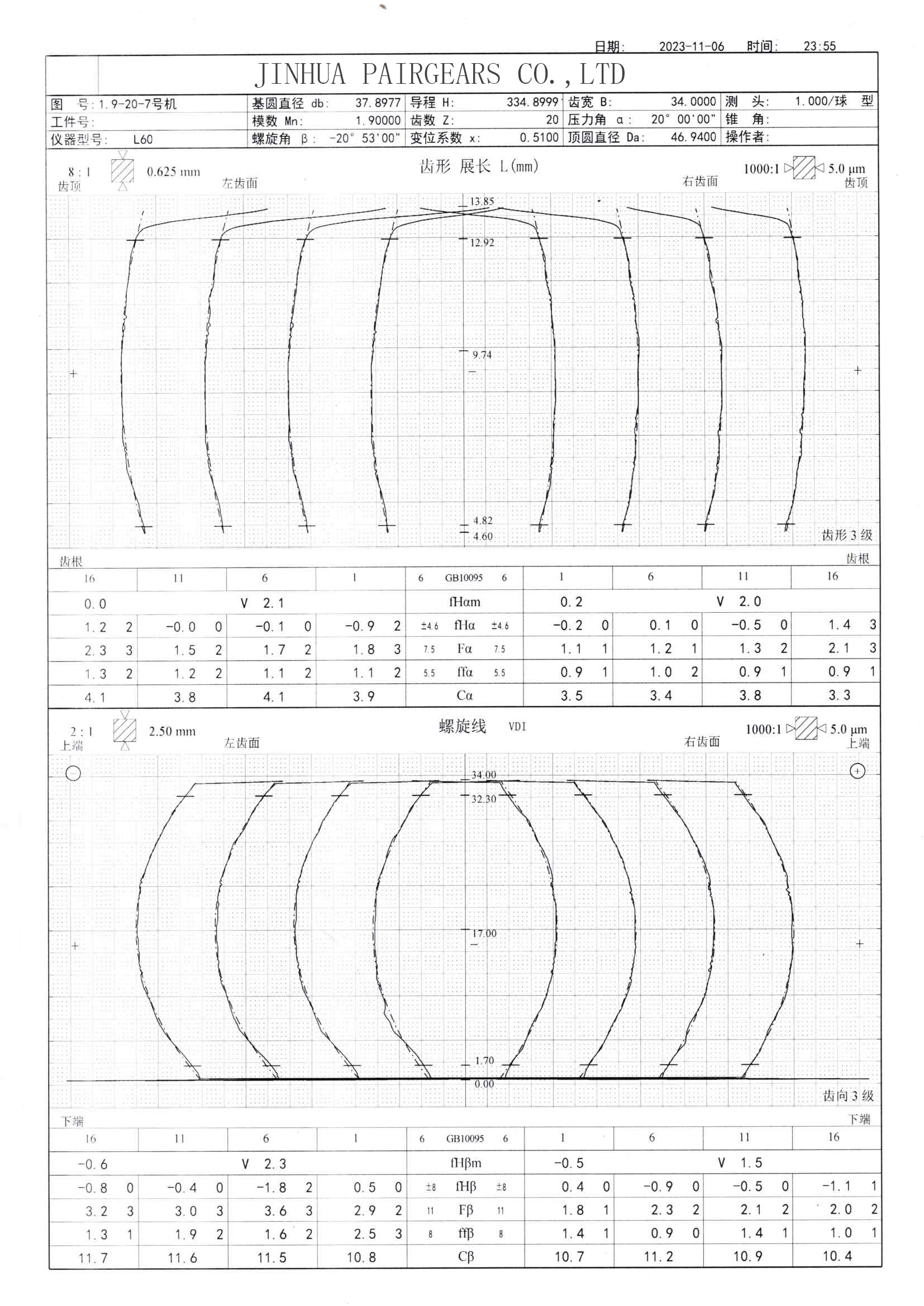

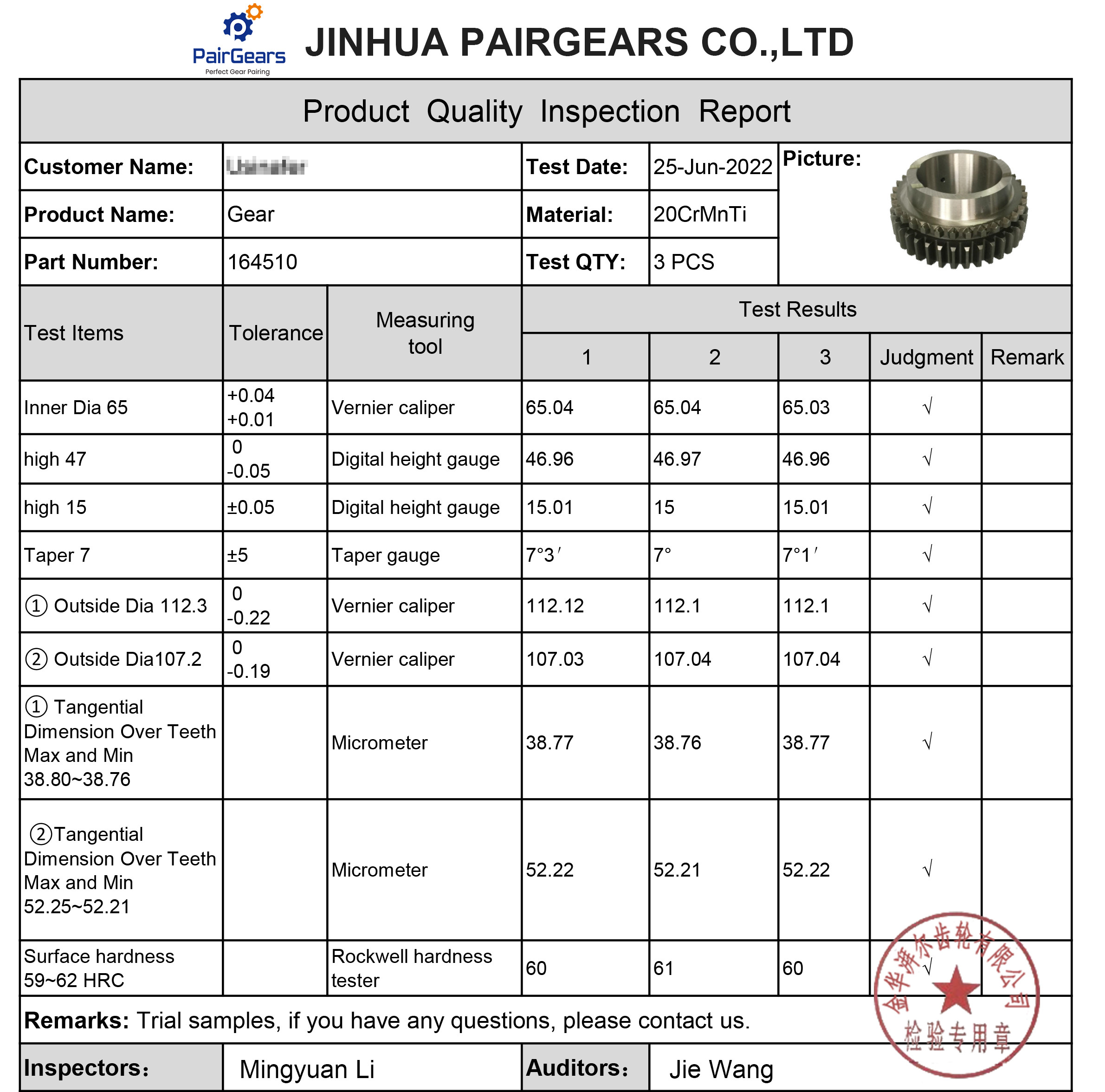

Dimension and Precision Inspection

Utilizing micrometers, gear inspection centers, and coordinate measuring machines (CMM), we conduct precise measurements of gear dimensions, tooth profiles, tooth spacing, addendum height, dedendum height, tooth thickness, and more. This ensures that the gear’s dimensions and shapes conform to design specifications.

Surface Roughness Inspection

Using surface roughness testers, we inspect the surface roughness of gears to ensure smooth surfaces, reducing wear and noise.

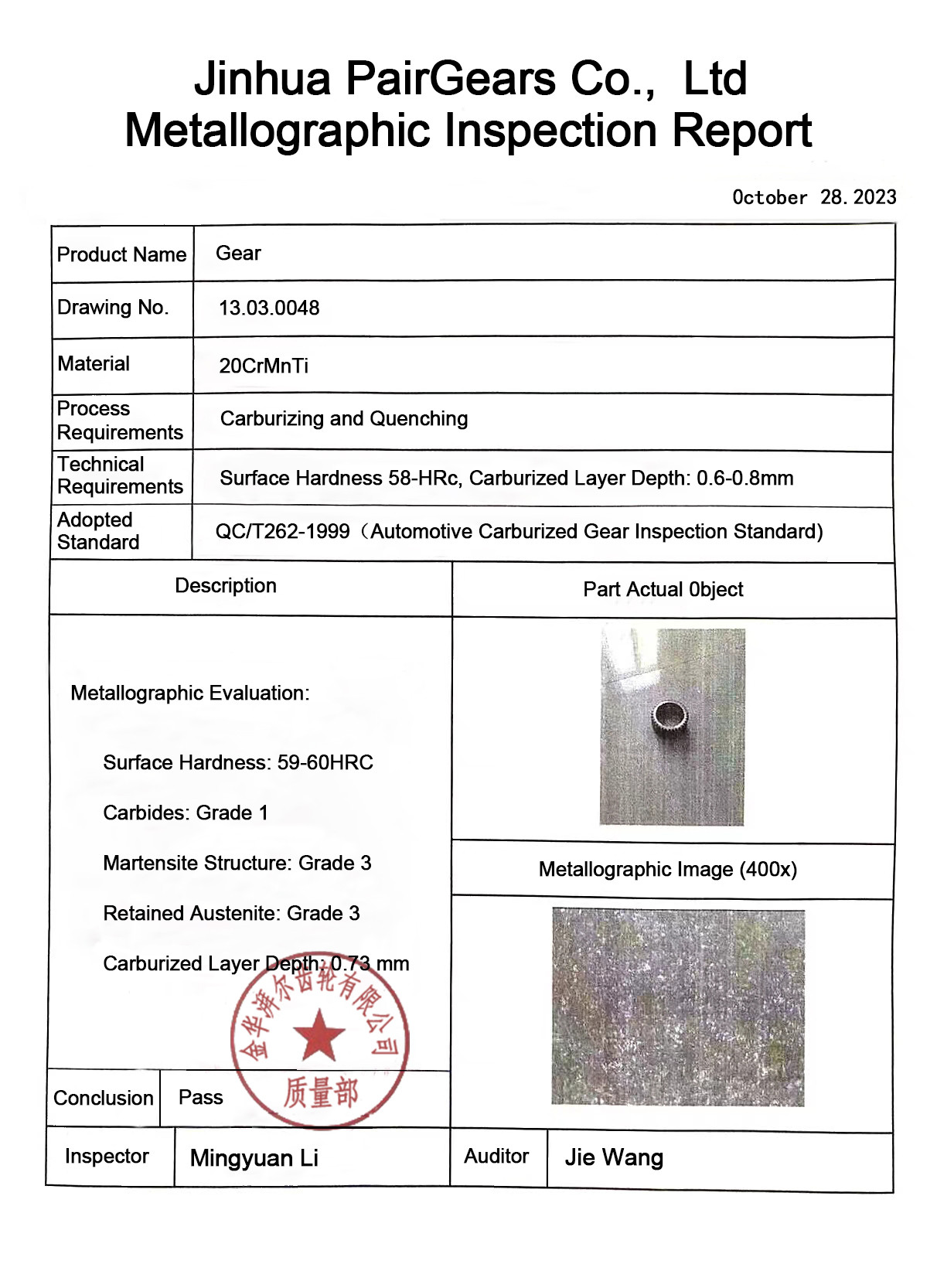

Material Performance Inspection

This includes chemical composition analysis, metallographic analysis, and hardness testing to ensure that the gear material meets design specifications with sufficient strength and wear resistance.

Post-Heat Treatment Inspection

We inspect the hardness and metallographic structure of gears after heat treatment to ensure that the hardness and wear resistance of the gears meet the design requirements.

By using gear strength testing machines, we conduct fatigue tests on gears to ensure that they will not experience fractures or other failures during long-term use.

We inspect the assembly fit of gears with other components to ensure that the gears are correctly positioned and operate smoothly within the transmission.

Evaluating the durability and reliability of the gears by simulating long-term operation under actual usage conditions.