The Importance of Gear Tooth Hardness and Surface Treatment

Introduction

Gears are integral components in various machines, from agricultural equipment to industrial machinery. The performance and longevity of these gears are significantly affected by their tooth hardness and surface treatment. Understanding these concepts is crucial for manufacturers and users alike, as they can enhance gear performance and reduce operational costs.

Understanding Gear Tooth Hardness

Gear tooth hardness refers to the resistance of the gear teeth to deformation and wear. Hardness is typically measured on the Rockwell scale, and higher hardness values indicate a greater resistance to wear. There are several key reasons why gear tooth hardness is essential:

1、Wear Resistance: Harder materials resist wear better, which is critical in high-friction environments. As gears mesh, the friction generated can lead to significant wear, reducing the gear's lifespan.

2、Fatigue Strength: Hardness contributes to a gear's fatigue strength, allowing it to withstand cyclic loads without failing. This is particularly important in applications like tractors and trucks, where gears are subject to repeated stress.

3、Performance Consistency: High hardness levels help maintain performance consistency over time, ensuring that gears function reliably under varying load conditions.

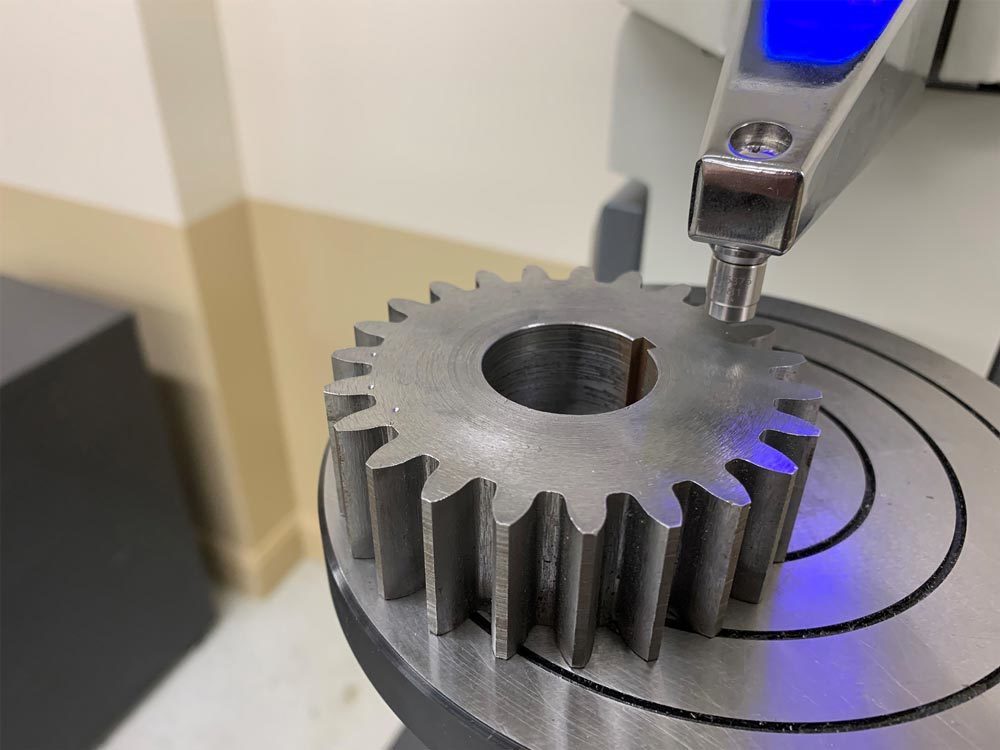

Pairgears also has strict hardness testing standards for gears, and can provide inspection reports.

Surface Treatment Techniques

While tooth hardness is vital, the surface treatment applied to gears can enhance their properties further. Several methods are commonly used:

1、Carburizing: This heat treatment process increases the surface hardness of steel gears while maintaining a tough core. Carburizing allows for improved wear resistance without sacrificing strength.

2、Nitriding: A process that involves diffusing nitrogen into the surface of the gear, nitriding enhances hardness and corrosion resistance. It is particularly beneficial for gears used in hostile environments.

3、Coatings: Various coatings, such as chrome or ceramic, can be applied to gear surfaces to reduce friction and wear. These coatings also protect against corrosion and improve the overall performance of the gear.

Impact on Gear Longevity

The combination of high tooth hardness and effective surface treatment can significantly extend the lifespan of gears. For instance, at PairGears, we ensure that our gears are manufactured using high-quality materials with advanced surface treatments. This approach not only meets industry standards but also provides our clients with reliable products that perform exceptionally well in demanding applications.

Conclusion

In summary, the hardness of gear teeth and the treatments applied to their surfaces play a crucial role in determining their performance and longevity. Investing in high-quality gear manufacturing and surface treatment processes is essential for businesses relying on gears in their operations. By understanding and implementing these concepts, manufacturers can produce gears that not only perform well but also last longer, ultimately leading to cost savings and increased efficiency.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.